B-Id is OEM/ODM Partner for Industrial Applications for 20 years!

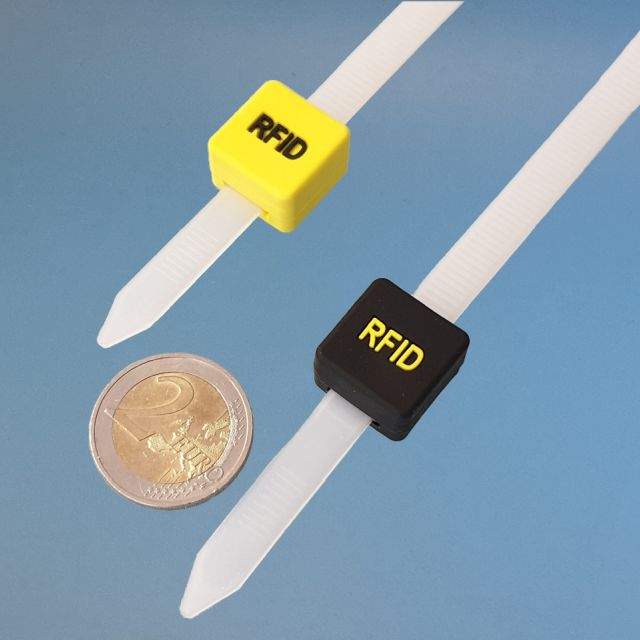

With 20 years of experience in the development and manufacture of RFID hardware, B-Id offers transponders for industrial applications that are specially adapted for use in challenging environments.

Depending on the requirements, the transponders are designed to function on metal surfaces, to be resistant to heat or to be used in the immediate vicinity of chemical agents.

The transponders are designed, developed and manufactured in six process steps: technology, design, material, tuning, prototype and series production.

1. Technology

B-Id supports customers with advice on the IC to be used as well as the requirements for ISO standards and desired reading range. The determination of these parameters, as well as the requirements and applications of the chip, whether a read or write function is needed and memory size are the first priority.

The following frequencies are available for selection:

- 125 kHz

- 13.56 MHz

- 868 MHz

2. Design

Depending on the size of the design, the selected technology is integrated into a standard product such as a key fob, tag or cylinder. Customized designs through adaptations or new developments of a tool or even a simple printing of a logo are realized.

3. Material

B-Id is specialized in the development of transponders for industrial applications. The choice of material determines the resistance to thermal, chemical or physical stress in harsh environments.

4. Tuning

B-Id makes adjustments to the antenna to achieve increased performance of the products with the readers used. These are tuned to external influences such as temperature or physical impact, additional programming or pre-programming for enhanced protection in the application is possible.

5. Prototype

The development of the prototype is the sum of all previous process steps. B-Id makes further adjustments and optimizations to ensure that the products meet the desired requirements.

6. Series Production

After approval of the prototype, mass production begins. B-Id ensures reliability and functionality of the products through quality control.

For a detailed consultation about services and products of B-Id GmbH & Co.KG, B-Id is of course personally available on the phone, in office but also gladly at your site of business. Contact B-Id!