Intelligent System from Balluff for Materials Management!

The new Smart Reordering System from Balluff makes it possible to monitor warehouse stocks fully automatically and to optimize the material flow. Manual and thus often error-prone processes become obsolete. Both material bottlenecks and overstocks are a thing of the past.

In many companies, production is based on the pull principle. This means that a service is only provided when it is requested, rather than continuously. This requires sufficient stocks of materials in order to be able to execute orders smoothly.

"Stocks are often still managed manually with kanban cards. In addition, there are fixed time intervals for material provision. Such processes are error-prone and inflexible," explains Sebastian Köhler, Strategic Incubation Manager at Balluff.

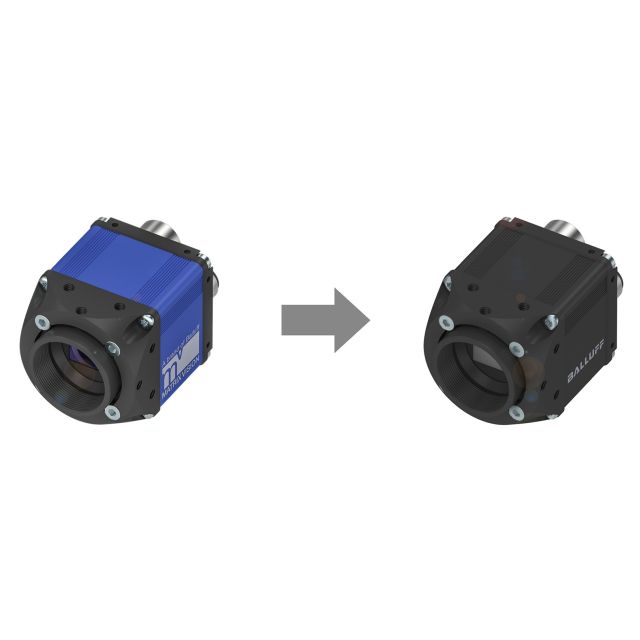

As a digital solution, the Smart Reordering System replaces manual processes and enables dynamic inventory management – either as a fully automated Kanban system or as a supplement to existing systems such as e-Kanban with RFID. The goal: to digitalize intralogistics.

In Just a Few Steps to Digital Inventory Management

As an Industrial Internet of Things (IIoT) application, the Smart Reordering System includes all the necessary components – from the sensor to the gateway and the cloud application.

Installation is quick: The battery powered optical sensors can be attached to the material location without wiring, regardless of whether it is a kanban shelf, pallet location, assembly workstation or delivery and pick-up location. Only the gateway needs to be supplied with power.

The connection to the system is made either via Ethernet or optionally with a SIM card. Users log into the cloud application, where the sensor data is processed and edited, via a web browser. Data security is guaranteed throughout the entire process, and no intervention in the existing IT infrastructure or additional software is required.

"Our pilot customers have especially appreciated the fast and uncomplicated installation of the Smart Reordering System. The major time and cost savings are also a major plus point for them," says Köhler.

Always Enough Material in Stock

The Smart Reordering System from Balluff avoids unnecessary material stocks that tie up capital and block storage space. At the same time, it ensures that sufficient stocks are available so that production does not come to a standstill.

When stock levels reach a pre-defined individual limit, the system automatically notifies the user. The user can also access the current fill levels on his personal dashboard in the cloud application at any time and from anywhere.

The data provided enables a comprehensive analysis of consumption. At the same time, this forms the basis for optimizing processes in production. Thanks to standardized interfaces, the Smart Reordering System can be linked to ERP systems and can trigger ordering processes automatically.