Digitally Supported Production Environment!

The ARENA2036 focus project DIREKT (Digital reconfigurable manufacturing of fibre composite components in a resilient production environment) has successfully been running since the beginning of 2020 as part of the Germany’s Federal Ministry of Education and Research (BMBF) funding scheme "Internationalisation of leading-edge clusters, forward-looking projects and comparable networks“ (InterSpiN).

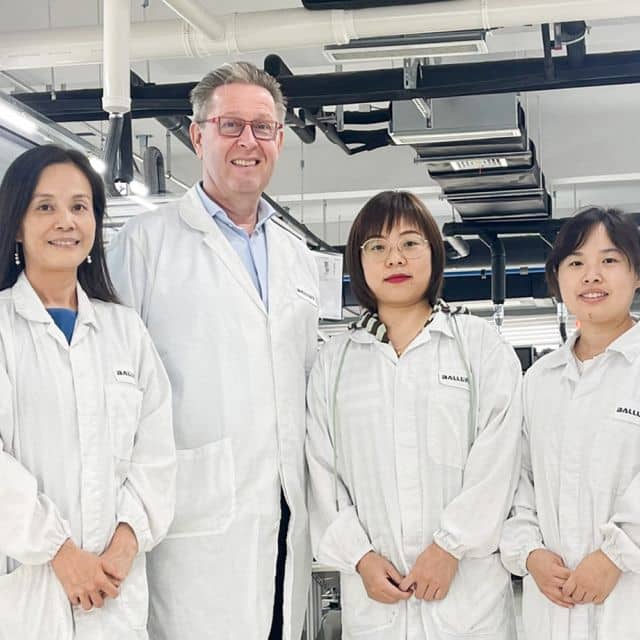

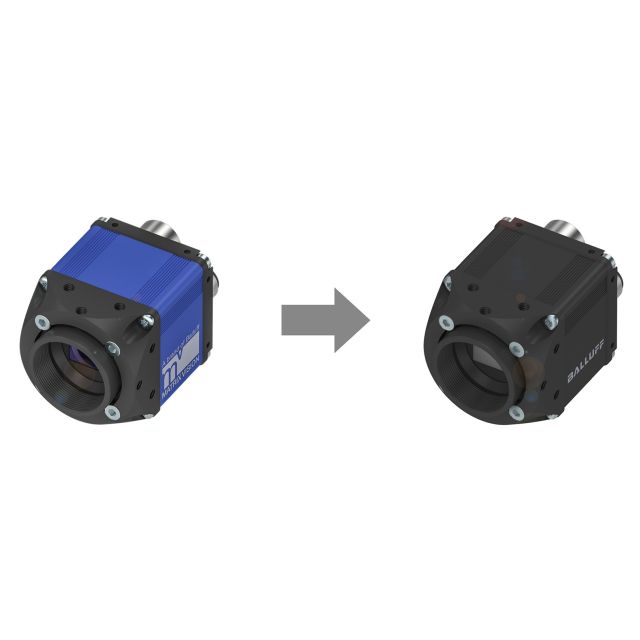

Balluff is involved as a project partner and is responsible for the front-end electronics, data transmission and evaluation of the entire process-related sensor technology.

DIREKT aims to develop a reconfigurable, self-monitoring and sensor-supported production environment for components made of high-performance fibre composites. The basis is formed by low-consumption lay-up processes for carbon fibre-based semi-finished products as well as shape-adaptive tools, which make the time-consuming and cost-intensive production of component-specific moulding tools unnecessary.

For continuous monitoring of the process, various sensors are integrated into the production environment at the Institute of Aircraft Design (IFB) in Stuttgart, Germany. This ensures an early intervention possibility, which is supported by instant data analysis in close proximity to production (edge computing).

The combination of digital production technology, shape-adaptive and automated manufacturing processes is expected to deliver a substantial reduction in product costs for small and medium volumes. As a result, customer-specific component geometries and the lightweight construction material like carbon fiber reinforced plastic (CFRP) can be realized in a wide range of applications.

Besides the IFB, the Stuttgart Media University (HdM), Balluff GmbH and CIKONI GmbH, a specialist for innovative fibre composite solutions, are directly involved in the project. CIKONI’s form adaptive DYNAPIXEL technology is utilized and further improved for customer-specific and one-off production of composite parts. The research group IAD (Innovative Applications of Printing Technology) at HdM deals with screen printing technology, which is used for the cost-effective and reproducible manufacturing of high elongation strain sensors in DIREKT.

The associated frontend electronics, data transfer and analysis of the complete process related sensor technology is enabled by Balluff GmbH, a leading sensor and automation specialist. “We will use IO-Link as an industrial communications networking standard (IEC 61131-9) for connecting digital sensors and actuators to an industrial fieldbus or Ethernet“, explains Albert Dorneich, Project Manager at Balluff.

The initial project phase has been successfully completed despite the applicable COVID-19 restrictions and the project partners are now intensifying their work in the individual areas.