..., B-Id develops tailor-made and high-performance transponders for the Industrial IoT.

RFID transponders are as available as sand by the sea. In order to select the right transponder for a requirement, many years of experience in the areas of chip selection, antenna tuning, and housing development are the fundamental prerequisites.

B-Id possesses the know-how from countless customer projects and can develop RFID transponders for even the most challenging applications based on this in-depth knowledge.

"An RFID transponder that is to be used in applications to optimize production processes must meet the customer's requirements 100 percent," reports Yiwen Jin, Managing Director of B-Id, and explains:

"In order to guarantee the functionality, we use in particular our extensive experience in the field of antenna tuning. Only an antenna that is perfectly matched to the application can provide a value-added solution. In order to achieve this performance, aspects such as the environment, materials on which the transponders will later be attached, and the possible existing RFID installations must be taken into account."

Plastic Expertise is the Key

In industrial processes, transponders are exposed to the prevailing conditions. High temperatures, oils, and chemical cleaning, or detergents or are factors that must be considered when developing customer-specific transponders suitable for industrial use. The housing is the decisive factor – this component determines the degree of durability.

"The plastic used is the central element in the development of extremely robust RFID transponders. Therefore, we work together with a very renowned and experienced company that specializes in the development and manufacture of plastic components for the automotive industry. Ultimately, our customers benefit from this materials expertise when they receive a transponder that is precisely tailored to the requirements of the environment in which it is to be used to optimize processes," says Yiwen Jin, giving an insight into the challenges of development.

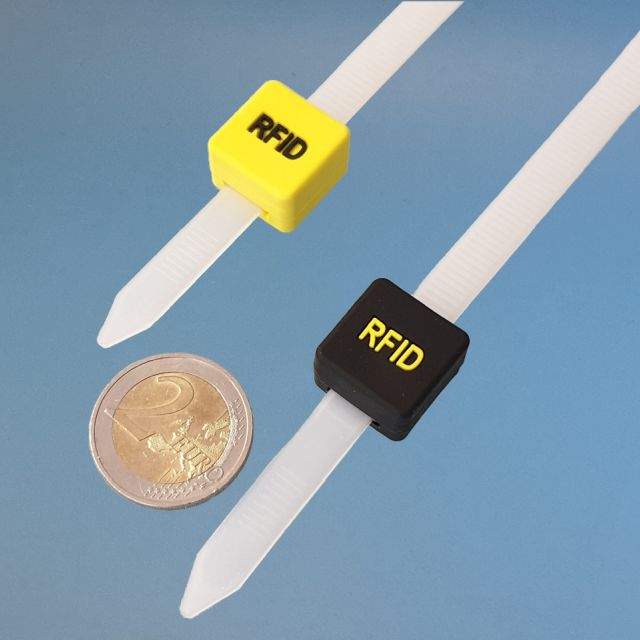

Latest Development: Flexible Industrial Transponders

Durable transponders that are resistant to extreme industrial influences are required in numerous use cases. However, if objects with undulated or curved surfaces need to be reliably and permanently labeled, RFID hard tags reach their flexibility limits.

"In order to support customers with these requirements, we have developed flexible RFID transponders that are suitable for industrial use. In contrast to an RFID label, they have a much higher resistance to abrasive influences and are therefore ideal for applications where non-planar surfaces are present," Yiwen Jin provides an insight into one of the latest B-Id developments.

Individual Tool Construction is a Major Asset

Numerous companies value the individualization of their transponders. The company logo should be strikingly visible, and the casing should be produced in the corporate colors, if possible. Nevertheless, some companies refrain from individualization because they assume high costs.

"This is where one of B-Id's greatest strengths comes into play," emphasizes Yiwen Jin, and explains: "With our extensive experience in the development of transponders, we have defined methods for producing individual tools at comparatively low prices. This lowers the cost of customization and is already being used by numerous customers – even on a larger scale: We have produced up to 40 different tools within a year".

How small can it be?

If a transponder is used to track a load carrier in a production line, the size of the transponder is not the decisive criterion. If, however, even the smallest component is to be marked with an RFID transponder, every millimeter count, says Yiwen Jin:

"If there are only a few millimeters of space available for attaching a transponder, there is hardly a way around ferrite materials. We use ferrites not only as the antenna core, but also as components in proximity of the antenna. Some time ago, we were able to develop a transponder with a height and diameter of only two millimeters."

The use of special ferrites enables the production of transponders that can be pressed flat into metal. The ferrite completely shields the antenna and chip from the physical influences of the metal.