Simple, safe and reproducible changeover for maximum machine flexibility!

Do you want to optimize your entire plant, avoid downtimes and realize shorter production runs? You will need intelligent machines and therefore intelligent production. This is already possible if a change of configuration, i.e. a conversion of your plant, is carried out in a guided manner.

For these semi-automated format changes, Balluff provides you with a digital position indicator, which offers clear operator guidance and reliable format change via its display. Machine damage and loss of production due to incorrect handling can be reduced to a minimum. Even untrained personnel quickly develop a routine in using our solutions to consistently perform changeover operations that meet targets and avoid errors.

With our digital position indicator, you can quickly and safely adapt to a large variety of products and ever smaller batch sizes. If you also use RFID, you gain a control function, because RFID enables the unique recognition of the different format parts. Here is how this solution works.

The digital position indicator - like the RFID technology used here - is part of our Smart Automation and Monitoring System SAMS, which consists of freely selectable components and devices. Its consistent operating and configuration concept, i.e. the look and feel of SAMS, increases machine flexibility and availability. This is because all SAMS devices can be parameterized and configured using standard data profiles and can even be taught-in on the tablet without contact, for example, with our BET engineering tool, software for easy setup of all IO-Link devices on your tablet or computer.

Guided format change with the digital position indicator

Balluff digital position indicators for safe semi-automatic format change have a display on which all of the settings for the format change (the new recipe) can be read. These are set manually by turning the spindle. The special feature here is that as a worker you are guided by a digital display of the values and by running lights.

- The running light shows you which direction to turn the spindle. The LED lights up red.

- If you approach the set value, the running light slows down. You can see at a glance that the setpoint is near.

- If the setpoint is exceeded during format change, the chaser changes direction and indicates that you must turn back.

This clear operator guidance and safe format setting using a digital position indicator increases efficiency. The times for a format change, the start-up time and the machine downtimes are significantly reduced. The bottom line is that you have the entire process under control, reduce waste and save money.

In the same time that you would otherwise use for repair and maintenance, your production is already running again, leading to more effectiveness and productivity. Also good to know: Our digital position indicator exceeds the IP69K degree of protection and meets the highest hygiene requirements. And it can be easily retrofitted into existing systems.

Exchangeable parts identification with RFID

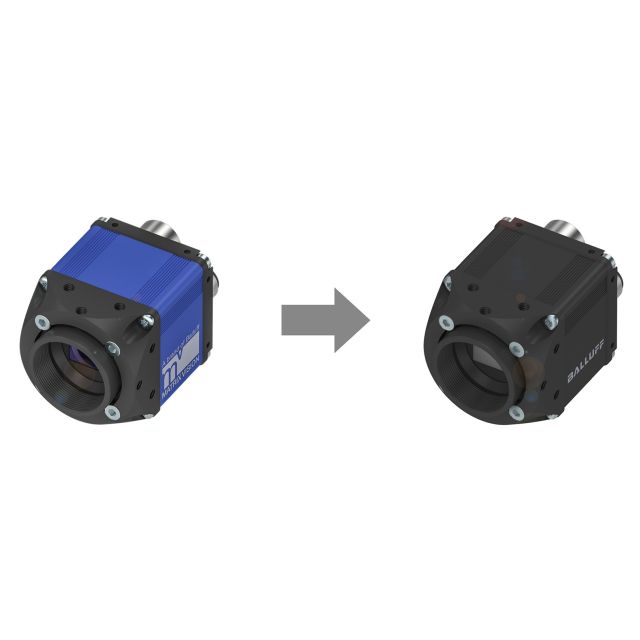

Once the correct format is set, our HF RFID technology (13.56 MHz) solutions offer you additional security by automatically identifying interchangeable parts. The different format parts are reliably detected and identified, with the technology even offering protection from counterfeits. Furthermore, you can use our vision sensors to detect whether the interchangeable parts have been installed correctly.

Various system combinations of evaluation units, read/write heads and data carriers are available for part identification. By selecting the components, you can meet various requirements for the detection of exchangeable parts. We can show you examples of which components are suitable for which applications. You can choose between the BIS V evaluation unit, an IO-Link network module as the evaluation unit and a read/write head with integrated evaluation unit.