RFID solutions for laundries!

In industrial laundries, it is important to keep capacity utilization and thus throughput as high as possible. Ultimately, unused capacity means weaker sales. The automatic recording of incoming and outgoing goods enables accurate and simple invoicing of services.

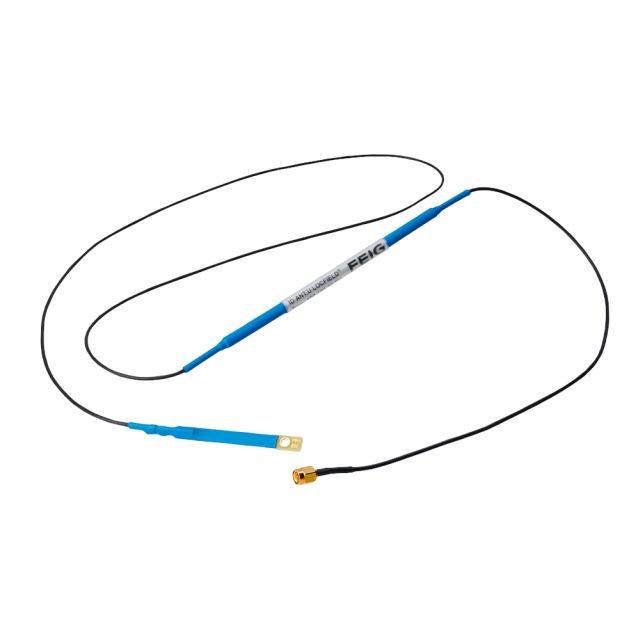

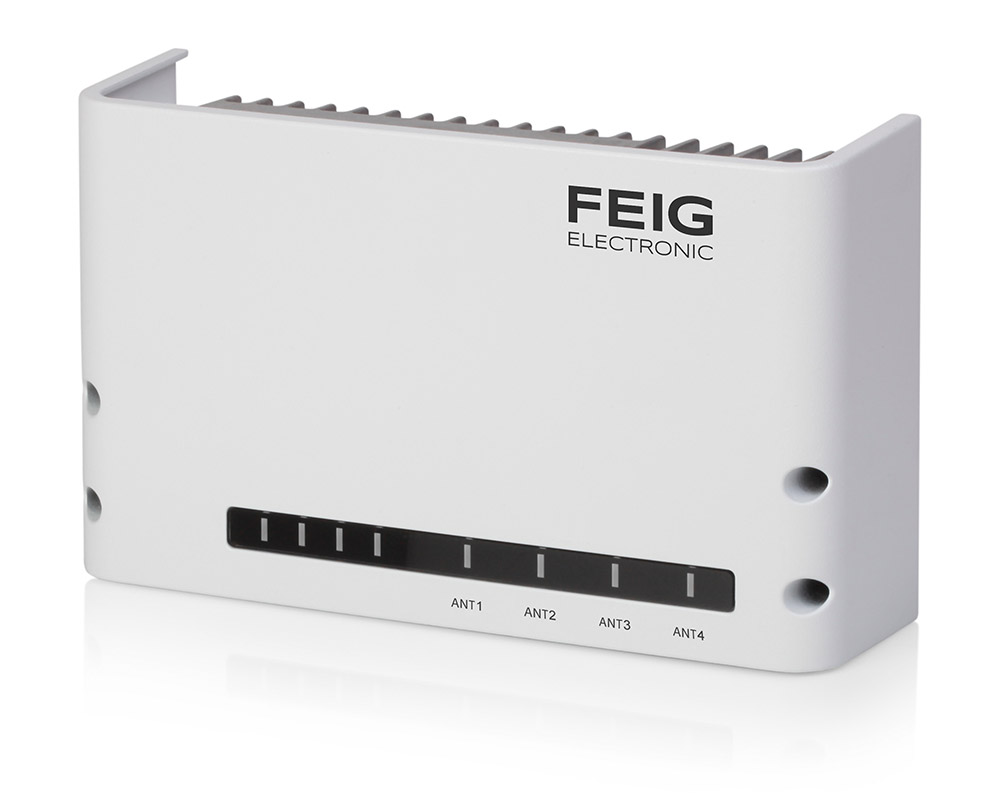

By automating workflows with RFID reader systems that quickly and reliably capture labels and transponders, processes in laundries can also be efficiently controlled.

High cost-efficiency thanks to automation

RFID systems enable rapid identification of individual laundry items for automated collection and sorting. This means that the number of manual work steps is reduced, which also decreases the potential for errors. The data-driven workflows ensure transparent processes. Additionally, RFID readers from FEIG ELECTRONIC are able to identify multiple laundry items simultaneously via bulk detection. This saves time and money because the items do not need to be separated in advance.

Data-supported processes increase transparency

Whether uniforms, rental workwear or bed linen - RFID-based systems give you full control over your data. In addition to the data on owner, order number or delivery date, the system can also track the frequency and number of previous laundering processes using the tag ID. In this way, inventory can be optimized and stocks and replenishments reduced.

At the same time, system recording during the transfer of goods enables automatic invoicing. Proof of services rendered can be provided in real time via RFID data.

Error-free laundry handling

Thanks to error-free assignment via RFID tag, you retain a permanent overview. This simplifies both internal and external logistics: laundry can be assigned to customer orders at any time, thus ensuring reliable handling - from incoming goods to control, automated billing, reworking and dispatch. What’s more, thanks to unique textile identification via RFID reader, the laundry items are always handled as intended.

Find the right solution for your laundry! Contact our sales team.