Highly Automated Sample Handling With HF RFID and Robotics

Beamlines Are in Operation 24 Hours, 7 Days a Week

ESRF – The European Synchrotron Radiation Facility in Grenoble: Each year, the demand to use these X-ray beams increases and near to 9000 scientists from around the world come to Grenoble

With a brand-new generation of high-energy synchrotron, the ESRF is the world's brightest X-ray source and a centre of excellence for fundamental and innovation-driven research in condensed and living matter science.

Samples are Exposed to Ultra-Bright X-Rays

The European Synchrotron Radiation Facility (ESRF) supports researchers worldwide in gaining insight into the atomic and microscopic structure of crystal samples. The ESRF's electron synchrotron, located in the immediate vicinity of the EMBL site in Grenoble, generates X-rays that are 100 billion times brighter than the X-rays used in hospitals to analyze the crystalline samples.

The ESRF helps researchers worldwide to gain precise insights into the atomic and microscopic structure of the crystal samples. Biological materials are studied in the beamlines of the electron synchrotron in order to promote the development of highly efficient medications, which, for example, should combat cancer more effectively.

Extreme Temperature Fluctuations between Storage and Analysis

The samples are stored in analysis tubes at negative 196 degrees Celsius. Examinations and tests are partly carried out at room temperature. The temperature fluctuations are enormous and components used, such as sample containers and sample holders, must withstand more than 500 cycles in individual cases.

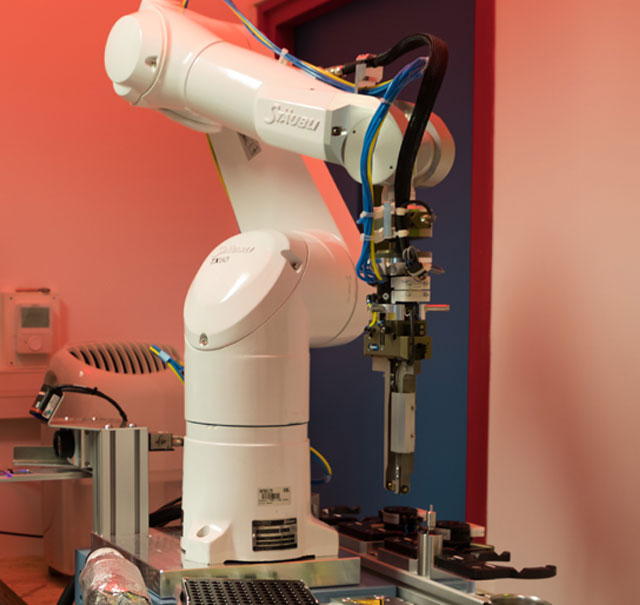

The increasing number of samples per year presented EMBL with the decision to develop an automated sample handling system in 2018. A new sample holder standard in combination with a robot allows testing the growing number of samples without additional manual effort.

Richard Aufreiter explains why the use of RFID tags is the best performing solution to ensure that not a single sample is lost in the automated process due to a missing tag.

„In the test series with more than 200,000 samples per year, RFID technology is essential for efficient and correct handling. The transponders withstand the extreme conditions such as cryogenic temperatures and high temperature fluctuations. HID's Piccolino tags manage the technological balance between smallest design and highest possible robustness. This results in safe and reproducible processes in the laboratory, " explains Richard Aufreiter the functionality of the RFID transponders.

Richard Aufreiter, VP Product Marketing, Identification Technologies, HID Global.

Extreme Temperature Fluctuations between Storage and Analysis

The samples are stored in analysis tubes at negative 196 degrees Celsius. Examinations and tests are partly carried out at room temperature. The temperature fluctuations are enormous and components used, such as sample containers and sample holders, must withstand more than 500 cycles in individual cases.

The increasing number of samples per year presented EMBL with the decision to develop an automated sample handling system in 2018. A new sample holder standard in combination with a robot allows testing the growing number of samples without additional manual effort.

„In the test series with more than 200,000 samples per year, RFID technology is essential for efficient and correct handling. The transponders withstand the extreme conditions such as cryogenic temperatures and high temperature fluctuations. HID's Piccolino tags manage the technological balance between smallest design and highest possible robustness. This results in safe and reproducible processes in the laboratory, " explains Richard Aufreiter the functionality of the RFID transponders.

Richard Aufreiter, VP Product Marketing, Identification Technologies, HID Global.

Richard Aufreiter explains why the use of RFID tags is the best performing solution to ensure that not a single sample is lost in the automated process due to a missing tag.