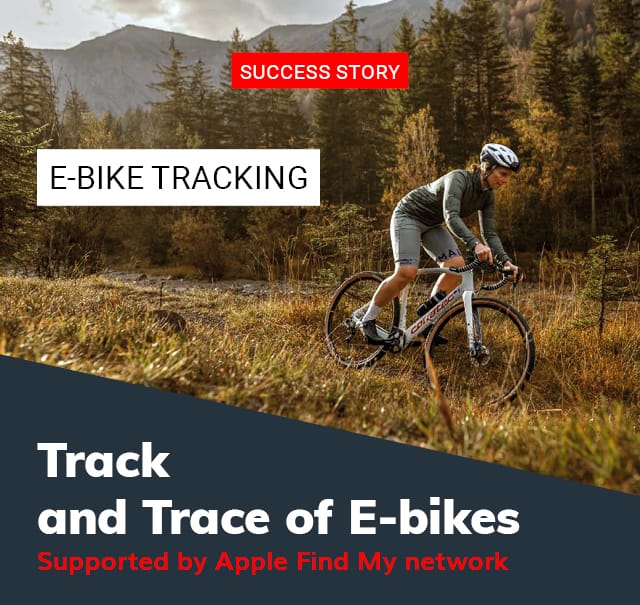

Track & Trace of E-bikes Supported by Apple Find My network

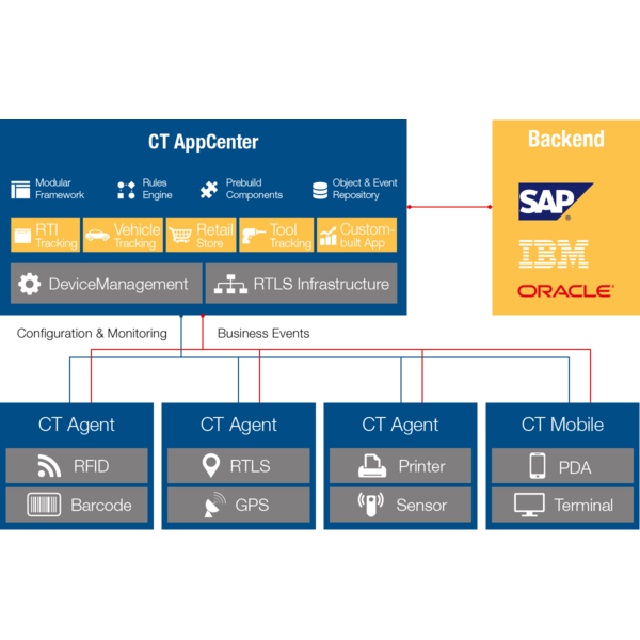

E-BIKE Tracking Even in the beer garden, a glance at the smartphone tells the pausing mountain biker that the high quality bike is still in the same place where he parked it. The more expensive the bike, the more reassuring it is to know that you can track it at any time, especially when it is out of sight. Iko Sportartikel Handels GmbH, a southern German bike manufacturer with worldwide distribution known for its premium brand Corratec, makes it easy for customers to quickly find their bike via an integrated module. Owners locate the lost object via the Apple Find My network. In order for this innovative tracking to be used in almost all Corratec e-bikes, the expertise of Kathrein Solutions was needed. A project as sporty as a mountain bike race. Success Story powered by: the Think WIOT Group, Iko Sportartikel Handels GmbH and Kathrein Solutions.