An Interview with Michael Kaiser

Which technological developments are currently being focused on at Kathrein Solutions? Which solutions are being implemented and what does the customer feedback look like? What direct influence does the commissioning of the new antenna measurement chamber in Stephanskirchen in 2019 have on product and solution developments?

The highlight of the current development: The upcoming re-design of the WiRa 30° Antenna in a new design and with highly optimized features.

In addition, new RTLS algorithms are currently being worked on. The focus here is on exact real-time capture of up to 30 centimeters in area and on switching to heatmap mode.

The challenge: To set up the system in such a way that exact capture takes place in one area while the RTLS transponder seamlessly switches to heatmap mode in another area! The solution should be available and ready for series production from 2021.

Michael Kaiser, Director Product Management & Innovations, Kathrein Solutions in an interview with RFID & Wireless IoT Global.

Which new products or product updates are currently being worked on at Kathrein Solutions?

Our focus on a modular platform enables us to react dynamically to different requirements. This allows our development team to create the right solution for our own products as well as for customer-specific OEM products. In terms of new products, new antennas and readers will be introduced in the coming months.

As a highlight, we see the upcoming re-design of our WiRa 30° Antenna in a new design and with highly optimized features. Our comprehensive UHF RFID reader portfolio will be rounded off with an ultra-compact 4-port reader.

Which development steps can be expected in the development of UHF RFID antennas and readers?

We are constantly developing our portfolio and adapting it to new standards and norms. The future-oriented modularity enables us to activate special functions via firmware updates. Our standard readers of the RRU 4500 and ARU 3500 series are equipped with a High Secure Memory module, which enables a high-performance decryption of data. The integrated Linux iPC enables high-performance execution of distributed software solutions and is thus optimally prepared for cloud architectures.

In which areas can optimizations be achieved with regard to performance parameters, such as range, sensitivity, and capture speed?

The Kathrein portfolio is already at a very high technical standard and achieves excellent results in many applications. Nevertheless, we are constantly developing our portfolio further. For range and sensitivity optimization, we rely on our own innovative Self Jammer Cancellation. This dynamically eliminates interfering signals in the receive path. While our high-end readers have already been equipped with an SJC solution for years, we will now follow this up with our entry-level readers and offer it as well.

For the capture speed, we offer optimized transmission profiles and rely mainly on our internal Linux PC. This PC can prepare and process the raw data captured via the rapid profiles. Thus there is no data delay even with a high data volume! Intelligent algorithms for filtering and decision making are also used in software development and our product CrossTalk.

What influence does transponder development have on antenna and reader development?

Which dependencies exist? Which of the two component areas sets development limits for the other side?

Here we see a very important factor influencing the overall performance of the system. A solution is only as good as the weakest link in the chain allows it to be! If the transponder sensitivity is missing, even the best high-end reader is useless. The key factor here is not a fixed limit, but the interaction of all parameters in the system. Our strength lies in determining these interactions and in forming an optimal solution from them.

We can fall back on our own developments in all areas and, for example, also offer special transponders that work best in the given application. Here, I would like to refer to our in-metal transponders, such as the RFID car license plate ePlate from Tönnjes, where we can transform metallic structures into RFID transponders. We have already been able to implement this embedded solution in a variety of applications, thus integrating metallic housings or attachments into the RFID system! In addition, we see the need to incorporate new transponder functions into RFID systems.

Years ago, we demonstrated this with the UCODE DNA chip from NXP and brought a high-speed solution for end-to-end encryption to the market. We have also recently upgraded our readers to capture the new augmented RFID chips from em|microelectronic, paving the way for a broad sensor solution.

With the Kathrein RTLS-N-1000 series, Kathrein Solutions has presented the first active, UWB-based RTLS.

What feedback have you received from users and will the first product series be expanded into a product family?

The feedback from the customers to our KRTLS was positive throughout! The first major rollouts, such as a pre-production vehicle registration system for a major European car manufacturer, went live in January. Further UWB projects are in the concept or pilot phase.

The extremely positive feedback and answers also allow us to move faster into the next development phase. We are working on further RTLS algorithms, which, in addition to high-precision capture (up to 30 cm accuracy), also enable dynamic real-time capture in the area, in order to generate so-called heatmaps, i.e. areas where motion profiles overlap.

The trick is to set up the system in such a way that the high-precision capture takes place in one area while the RTLS transponder seamlessly switches to heatmap mode in another area! This solution will be ready for series production in Q2/2021.

Following the integration of UWB technology in Kathrein Solutions' IoT portfolio, are there plans to include other technologies, such as BLE or LPWAN, in the product development?

If not: Why will the focus remain on RFID and UWB?

In principle, we are open to all wireless technology solutions and use them for the benefit of our customers. For instance, we have already installed a BLE module in the RRU 4560 and ARU 3560 in addition to the WLAN interface in order to offer an additional data interface. We also incorporate UHF RFID and NFC in our RTLS transponders, in addition to UWB technology. They are connected to each other in such a way that data and applications can be exchanged. We call these CrossLink functions.

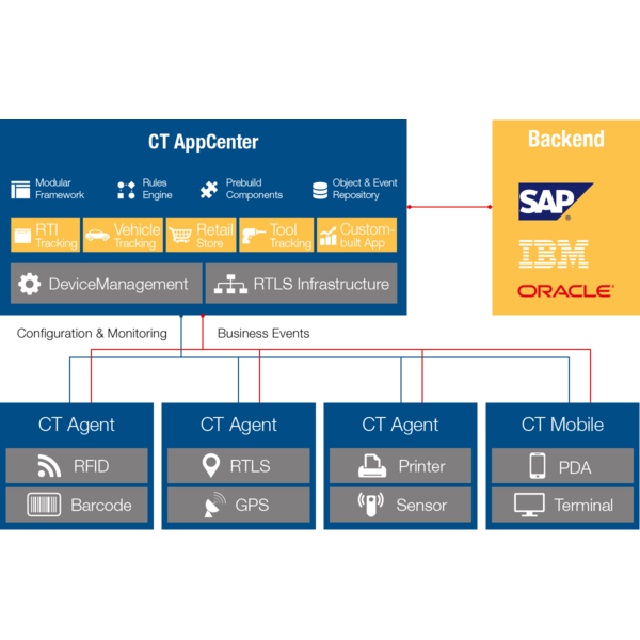

In addition to this HW-based approach, we can always integrate customer requirements for further technology interfaces via our CrossTalk platform. This is where CrossTalk's solution concept with distributed agents integrated into the backend servers becomes ideal. It is irrelevant which technology is used and which hardware solution is preferred. Generally, we can upgrade any hardware and integrate it into the overall system, regardless of whether Kathrein is on the nameplate or not.

With CrossTalk, we have been pursuing this 3rd party capability from the very beginning and will continue to keep this path open in the future!

What direct impact has the commissioning of the new antenna measurement chamber in Stephanskirchen in 2019 already had on product and solution development

with regard to shorter development times and reduced costs, as well as the solution of previously difficult challenges?

This new antenna measuring chamber was one of many steps towards an even more powerful future. Ultimately, we have further expanded the location in Stephanskirchen and combined all competencies. We concluded this with the relocation of the headquarters to Stephanskirchen. Unfortunately, due to Corona, the inauguration ceremony of the new office rooms had to be postponed indefinitely.

However, we will make up for this in 2021 in order to set milestones together with our partners and customers. The new measuring chamber will help us achieve this goal, as it allows shorter development times and, above all, doubles our test capacities for customer applications. In other words, it's a win-win situation for our customers and partners!

Source: RFID & Wireless IoT Global, Special Edition Wireless IoT Technology 2020