By Means of RFID Technology without a Pit Stop!

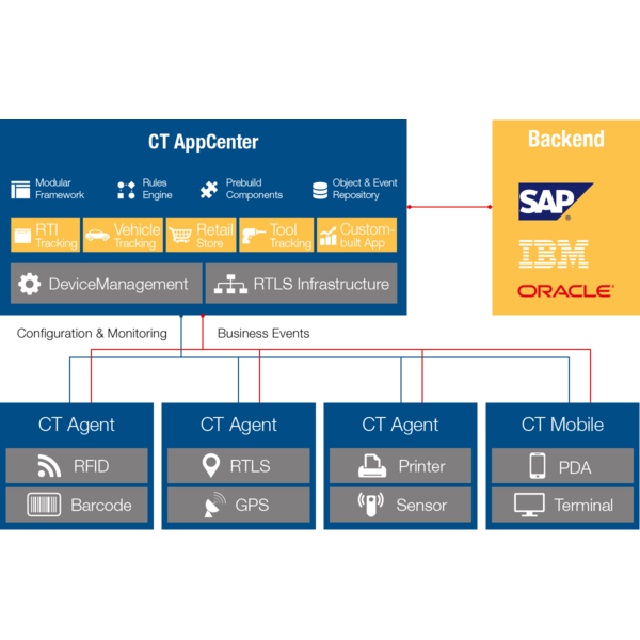

RFID by Kathrein Solutions as a tool: As a production or logistics manager, you must be able to process customer orders quickly. There is no time to search for the required number of load carriers or containers. At a glance, you want to identify reserved and free capacities in order to allocate them to a new order.

RFID-tagged, digital load carriers bring transparency, control and management to your intralogistics.

Everything at a glance using RFID technology: This requires transparency and control. And all this in real time: Where are the load carriers currently located? What condition are they in? When and where will additional containers be released? Costs always rise when containers disappear, or unnecessary safety stocks are built up just to remain capable of acting. If load carriers are soiled or defective or employees are busy searching for free capacities, costs rise. A standstill in production even puts your delivery promise at risk.

Optimise your load carrier pool according to your needs and gain planning reliability. This ensures high availability and prevents bottlenecks. With the RFID-based digitalisation of your load carriers, you "marry" their contents and the box. This facilitates SMART plausibility checks serving the purpose of quality assurance.

Using RFID load carriers, you are perfectly equipped for logistics and production 4.0.

Stock transparency of load carriers

RFID-tagged load carriers provide you with transparency about their:

- Quantity

- Location

- Status (empty, full, defective, service, etc.)

- Availability

Material flow tracking

If you "marry" the load carrier ID with the material data, you avoid errors in the material flow by plausibility checks on:

- Transport status

- Batches

- Replenishment

- Current storage location

Production flow control

A continuously digitalised and plausibilized data flow secures your production processes and provides error-free just-in-time deliveries of

- raw materials and semi-finished products

- at the respective production stage / per batch

- including automatic production postings

- as well as plausibility checks for the monitoring of or compliance with production processes