Murata Delivers End-to-End Solutions through Consultancy, Hardware & Software

Murata ID Solutions is a systems integrator with over 20 years of experience in RFID research and development. As a European competence center for complete RFID solutions, Murata ID Solutions has pioneered the industry with the development of innovative products and solutions. Through consultancy, hardware, and software, Murata provides clients with all the necessary building blocks required for RFID deployments and delivers complete end-to-end solutions. Prof. Antonio Rizzi, Founder and Vice President of Murata ID Solutions, explains Murata’s unique approach to RFID deployments.

1. What is Murata’s approach to RFID development?

Prof. Antonio Rizzi: Together with the RFID lab at the University of Parma, we have developed a structural approach to RFID projects. What we provide is not only the product but the value enabled by the RFID project in its entirety. This unique approach consists of three main pillars: consultancy, hardware, and software.

2. What role does consultancy play in this approach?

Rizzi: Consultancy is the first pillar in this approach. The key is an in-depth comprehension of how to create value. Murata ID Solutions, that stems from the Industrial Engineering Department of the University of Parma, initially approached RFID by deeply analyzing and understanding how to create value in business processes in the supply chain through RFID and the IoT in various industries, including pharma and healthcare, fashion and apparel retail, FMCG and food.

The first step, ahead of any RFID venture, is to draw up a “feasibility study”, a blueprint that sets out the parameters, key action points and expected outcomes of the project. In this “feasibility study” we examine the current supply chain and retail processes in depth, highlight criticalities as well as opportunities for RFID deployment and create a roadmap for RFID implementation, including related costs. On top of that, we provide a full calculation of the projected discounted cash flows and ROI associated with the project. We call this approach the “Doctor’s Approach”.

3. What is the ‘Doctor’s Approach’?

Rizzi: Many companies approach RFID from a tech point-of-view. Conversely, we start from the question ‘why?’. This is the ‘Doctor’s Approach’. As the doctor moves through a symptom – diagnosis – prescription approach, giving a prescription only after examining the patient, we first need to identify and understand what kind of issues our customers are facing and the opportunities they would like to seize. We focus on ‘why’ our clients require RFID implementation (symptoms). Next step is the diagnosis: we define the data needed to solve the issues and if the technology can provide that data. And lastly, we proceed with the prescription, where we design and create the RFID system able to generate those data. Simply putting the technology in place will not work because data is the key. Furthermore, processes often have to be changed to leverage the technology and stem those data.

4. What kind of value can be created with RFID implementation?

Rizzi: RFID is the key to hidden value and can be used for tracking, tracing, and managing inventory throughout the entire supply chain. Data from RFID tags can be used to remotely monitor the flow of goods and gain valuable insights into products’ identity, status, and condition. With the unique identity that RFID provides for each product, you can ensure brand protection and prevent unauthorized modifications or replications. This, however, is only the tip of the iceberg of what is possible with RFID!

5. After consulting with a client, what is the next step?

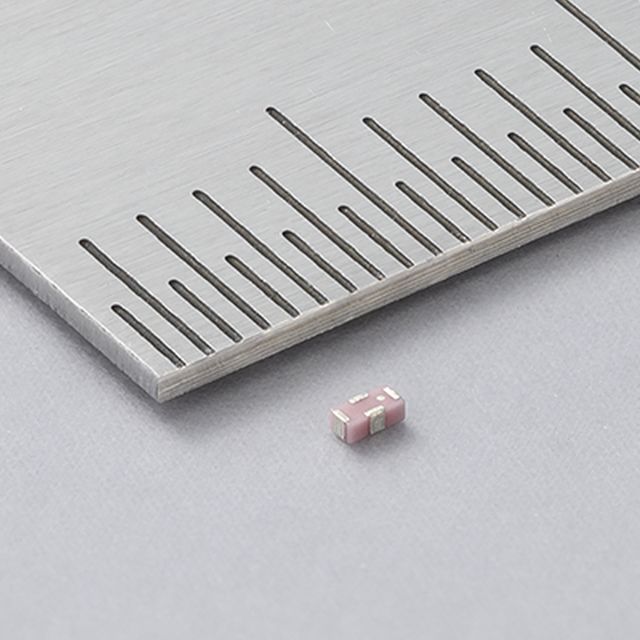

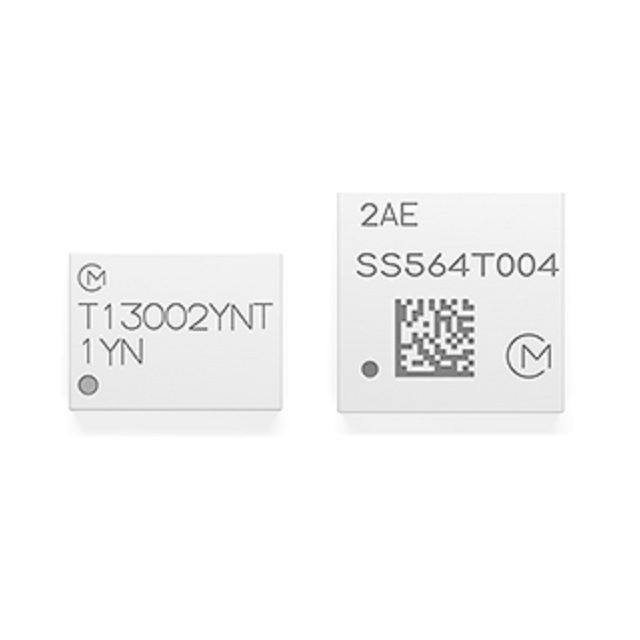

Rizzi: The next step is hardware selection. We offer clients a complete range of RFID hardware supplied by selected partners. These include RFID handheld readers, fixed readers but also equipment we engineer such as RFID gates, smart tables, tunnels, cabinets, etc. that best suit the use case. Murata also provides a wide range of RFID tags. All selected tags are subject to extensive testing at the University of Parma and Murata’s anechoic chamber.

6. The third pillar of RFID development is software. What kind of software does Murata offer?

Rizzi: Murata has developed a platform called id-BridgeTM 4.0 middleware and dashboard suite. This platform consists of an RFID middleware and an RFID business intelligence dashboard. It enables businesses to get the maximum benefits from their RFID applications.

7. How does the RFID middleware function?

Rizzi: Simply put, the id-BridgeTM Middleware is a software layer that is responsible for the remote management and control of the RFID hardware. The installation can be either cloud based or on a virtual/physical server in the customer’s cloud/server farm.

The middleware monitors the RFID hardware and translates raw RFID reads from the field into data manageable by the legacy systems. The integration of RFID devices with legacy ERP systems, like SAP, JD Edwards and many others, is smooth and frictionless. Moreover, the id-BridgeTM Middleware includes an object-oriented web browser interface that facilitates the set-up, control, and maintenance of an RFID deployment.

8. What are the advantages of the RFID business intelligence dashboard?

Rizzi: The second part of the software is the cloud-based RFID business intelligence dashboard. Every RFID event is tracked in a cloud-based data warehouse system that feeds business intelligence modules. They show the status and condition of products, inventory levels, KPIs and traceability data. Moreover, records are stored in the dashboard using standard formats like EPCIS. This allows standard data, easily interpreted via Json APIs, to be shared with stakeholders.

With the id-BridgeTM Dashboard, managers at every stage of the supply chain can quickly access the information they require every day, everywhere on the web interface. They can get valuable insights on supply chain operations or even receive an AI powered alert if something wrong/unexpected happened or is going to happen and take the necessary action in real time or even in advance.