Rethink, Recover, Repair, Reuse, Recycle.

These are the 5 key pillars of a strategy to support circular economy in the textile industry, the 5R strategy.

Primo1D explains how recycling is a key step that closes the loop of circular economy. It redirects already-existing materials in the manufacturing process.

Textile Recycling Ecosystem

Textile articles are made of many various materials: biological materials (cotton, lyocell, wool, etc.) and synthetic materials (polyester, polyamide, elastane, etc.). Sometimes, very different materials find themselves assembled together in a single article.

Recycling process complexity comes from this diversity of materials and hybridization possibilities. Recycling requirements also differ with the wanted materials at the end of the process.

The French eco-organization Refashion built a map of textile recycling processes that highlights this complexity.

Embedded RFID Upgrades Sorting

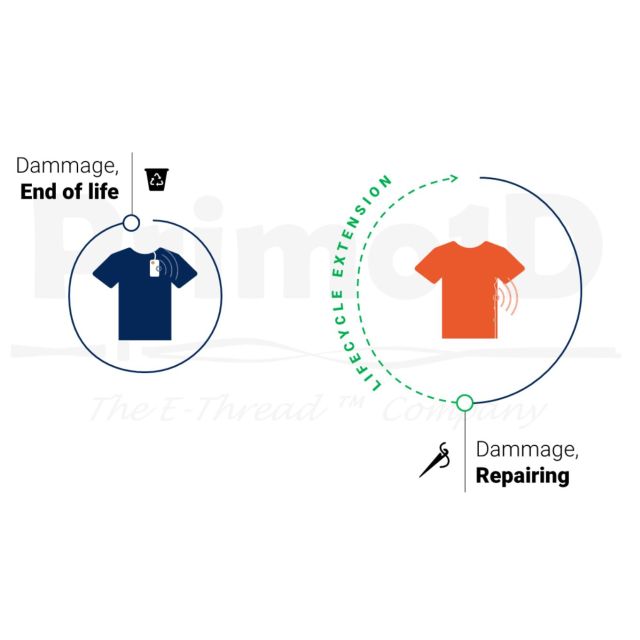

Today in sorting centers, trained operators identify clothes and garments manually. The first step to sort garments out is to figure out if garments can be reused and redistributed amongst consumers as second-hand purchases. When articles are not compliant with reselling requirements anymore, they are sent to recycling for their end-of-life. Two major difficulties are then pointed out.

Materials Identification

The first difficulty is the identification of garments materials. This information is mandatory to choose the right recycling process which, as seen previously, can be complex. Moreover, this information is indicated on garments detachable labels, which are cut most of the time for the consumer’s convenience.

In addition, many sorting errors can come from the manual nature of operations.

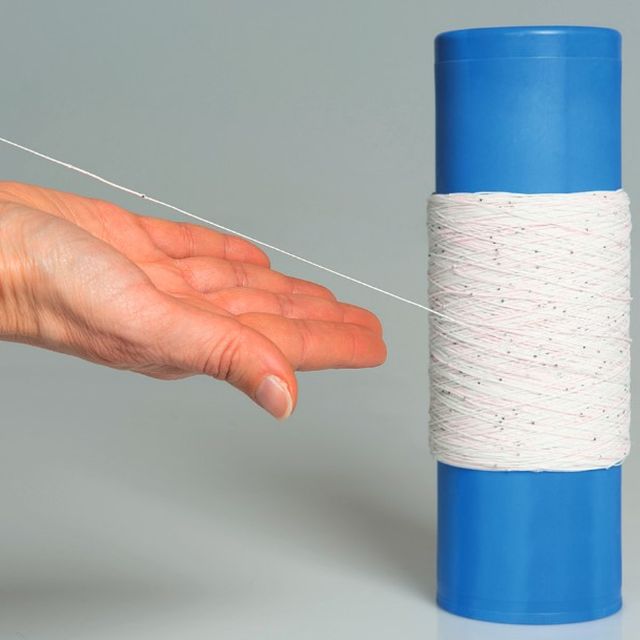

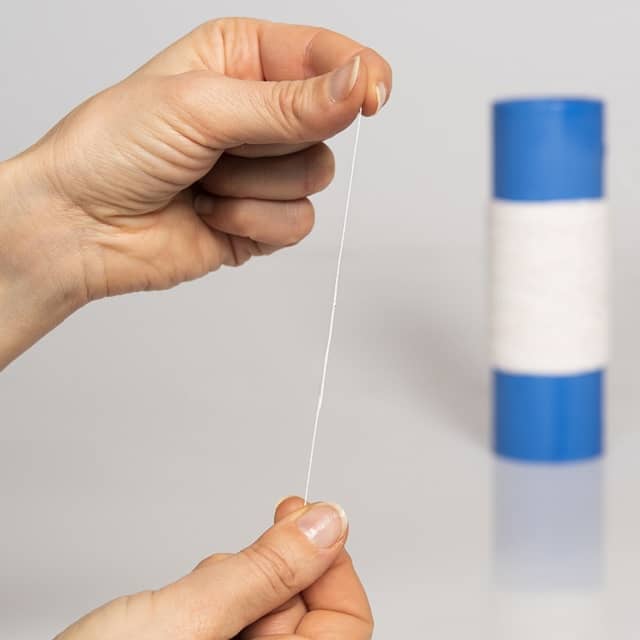

Embedded RFID is a real lever. Associated with its article, it ensures information access continuity and therefore facilitates sorting processes and prevents from polluting end-of-life.

Sorting Automation

The second obstacle is the sorting capacity of the centers against the amount of textile waste being generated every day. With the upcoming regulation evolutions in Europe, this amount is likely to increase very rapidly. France, for example, aims to sort at least 50% of its textile waste by late 2022 (38% in 2021). Moreover, at least 95% of the collected textiles must be sorted (78% in 2021)1.

The French government supports R&D efforts to enhance sorting operations:

Embedded RFID is a real answer. Not only does it make information reliable, but it also opens automation solutions in sorting centers by steering articles towards their recycling process.