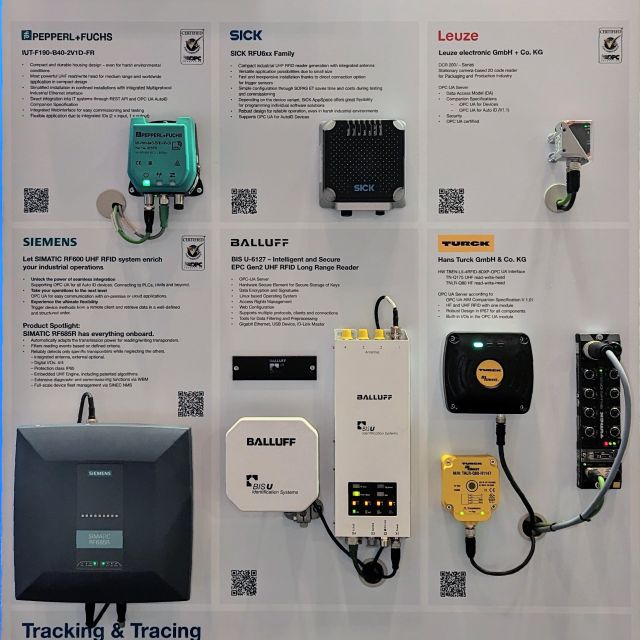

Find Your RFID & Wireless IoT Product :

Easily locate what you need – and more!

Our Product Search is designed to provide you with detailed information about state-of-the-art wireless technology, applied in the development of innovative products that are of high quality, customisable, flexible, and designed to make life easier for the end-user. All categories have been chosen carefully to make this search engine as user-friendly as it can be. If you hover your cursor over an individual filter, it will display more information. If you wish to clear one or several filters, you can do so by clicking on them a second time.

High-quality products – Custom-made!

At the bottom of the page, you can choose a Brand filter, if you are looking for a product from a specific supplier. If not, you can pick from our Product Categories at the top of the page. The categories of Technologies, Range, Reader Design, Data Carrier Design, Component Type, and Harvesting allow you to specify the search further, depending on your selected product category. Every product entry provides you with a link to the supplier profile, where you can find more information about the company, including their other products, solutions, and press releases.

Narrow down the possibilities!

The filters for our Application Fields category give you the option of browsing multiple areas of application in which the listed products are being or can be used. Whether you are looking for products particular to Industrial or Consumer IoT, Asset Management, Logistics, Retail, Healthcare, or Security, these filters help you narrow down your results.

Made to last!

It is essential that a chosen product it perfectly adjusted to the environment it is to be used in. Be it extreme temperatures, extreme pressure, military usage, or lack of space, a product has to be manufactured and tested to make sure it withstands what it needs to. If you are looking for space-saving, water- and dust-proof, or metal compatible products, simply utilise our Environment filters to guide you in the right direction.

Additional features: The future in mind!

The products available in this search engine have been manufactured with the fact-paced environment of the digital age in mind. Whether you are in need of options that offer Sensor technology or Data Encryption for top-notch security, the filters in the Data Handling category assist you in finding the right fit for you.