Double Interview at Balluff on Research Activities

Balluff: The Symbiosis of Hardware and Software

Balluff Interview on Network Technology

A Glimpse into the Future With Balluff's CEO Florian Hermle

RFID goes mobile - Traceability for LF, HF and UHF applications

Coming Soon: Balluf's Condition Monitoring Sensor BCM Generation 2

Balluff: Production in Mexico in Ramp-Up

Balluff Grows in China

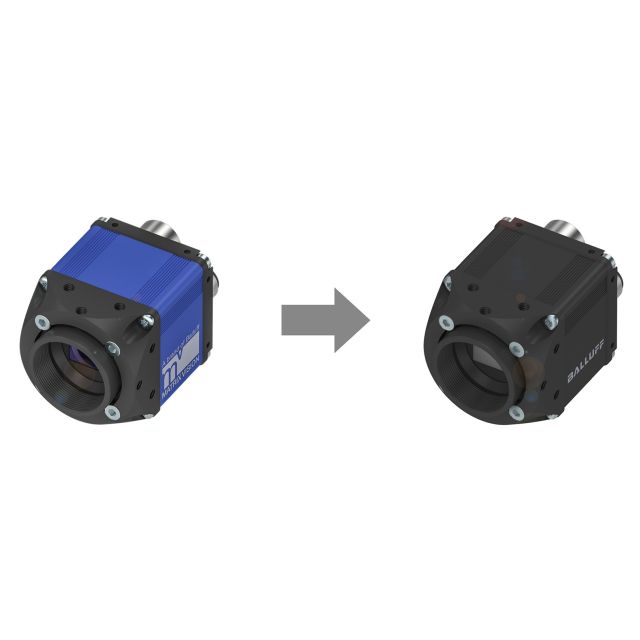

Matrix Vision Rebrands as Balluff

Balluff Receives "Bosch Global Supplier Award"

Balluff Expands Capacities in China

Balluff: Continuing on a Growth Course

We improve our customers' competitiveness by accompanying them long-term in their business processes and opening up new perspectives through our passion for automation. With our comprehensive portfolio of high-quality sensor, identification, and image processing solutions as well as software, we offer holistic solutions, connecting OT with IT and guiding our customers step by step to the smart factory.

Florian Hermle, Managing Director, Balluff

Balluff

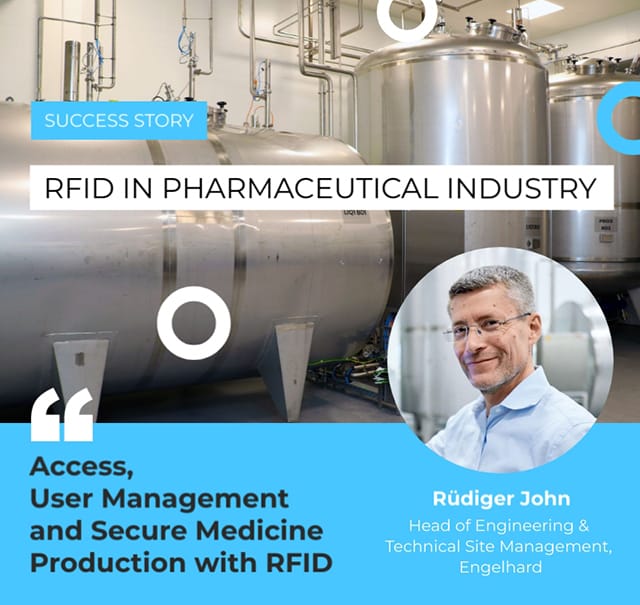

With over 40 years of experience in the area of RFID, Balluff holds a position as a global leader with industry-proven LF, RF, and UHF solutions for extremely rough environments. The product portfolio includes

- Complete system solutions, starting with the analysis of the current situation, through consulting to implementation

- Extensive selection of robust transponders, also for use with metal and at high temperatures

- Customer-specific development

Global leader with industry-proven LF, HF, UHF solutions

With more than 6 years of experience in industrial automation and over 40 years of competence in the area of RFID, Balluff is a committed partner with industry proven LF, HF and UHF solutions for rough environments. The product portfolio includes stationary and mobile read / write devices, controllers, antennas, and transponders.

Robust RFID solutions for industrial use

Balluff RFID systems help at solving nearly every application requirement. They are used, for example, in production control, counterfeit protection, tool identification, kanban systems, or goods tracking and traceability solutions. Long-term experience in RFID applications with profound technological competence provides the basis for custom-tailored RFID solutions.

With the connection of sensors, bus, and network components and the development of ideally interlocked software tools and solutions, Balluff also offers holistic digitalization and Industrial Internet of Things (IIoT) solutions.

Supplier Excellence

Technologies

Application Fields

Get in touch with our experts