440,000 items of tagged laundry are controlled by RFID and in-house developed software

The textile services company Sicking in Münster has developed and integrated its own system to transparently control laundry processes with HF and UHF RFID technology, and to precisely localize laundry items. An in-house programmed software processes and analyzes all RFID data captured.

The benefits: Manual errors are minimized, machine utilization is optimized, and transparency is increased. Customers can also view live data via a web portal. The next step: The installation of a fully automated sorting system, which is currently under construction.

Alexander Wildschütz, Managing Director of the textile services company Sicking in an interview with RFID & Wireless IoT Global.

A 4th Generation Family Business

The siblings Moritz and Alexander Wildschütz are the fourth generation to run the textile services company Sicking in Münster. The family business is part of the Servitex Group and employs 60 people. The company's fleet includes a total of eight trucks that supply customers within a radius of up to 150 kilometers with laundry. Around twelve tons of laundry are processed every day.

Starting with HF RFID Integration

"The trigger for the use of RFID technology was the necessary optimization of process control in the workwear sector. Originally, our company was mainly represented in the hotel and gastronomy sector. The customers' requirements included clothing that was sorted according to employees and exact traceability," says Alexander Wildschütz, explaining the beginnings of the solution integration. To meet these needs, the textile services company Sicking set itself the goal of designing its own system.

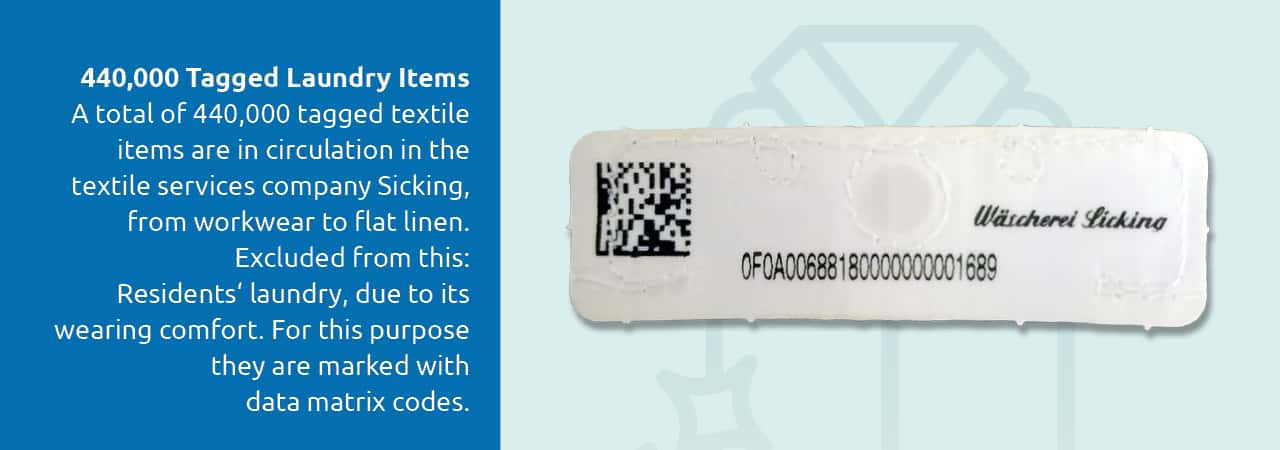

440,000 Tagged Laundry Items in Circulation

The textile services company Sicking continuously patches pieces of laundry with RFID transponders, enabling tracking & tracing via a web portal for customers. Additional services include on-site sorting and comprehensive checks of the textiles according to customer requirements, for example checking reflective strips on safety clothing. All control data is stored in the system.

Thus, it is possible to trace when which check was carried out. "In total, 60 percent of the laundry we process comes from the hotel and catering industry. Almost 30 percent concerns workwear and the remaining 10 percent concerns care facilities," says Wildschütz.

Over 90 percent of workwear has already been tagged, which corresponds to a total of around 190,000 individual items. 30 percent of flat linen is also tagged with an RFID chip, which corresponds to around 250,000 items. Customers' own textiles can also be tagged by the laundry in order to provide these customers with the same services via transparent processes. Due to their wearing comfort, laundry items worn by residents are completely excluded from RFID detection. These will continue to be marked with data matrix codes.

Starting with HF RFID – UHF RFID Since 2019

The technology integration took place in 2012 with HF RFID. "For the laundry sector, HF RFID was state-of-the-art eight years ago. At that time, the detection of UHF RFID transponders in the challenging environment of laundries could not be controlled with comparable accuracy using the available antennas," explains Wildschütz.

Sicking then switched to UHF RFID at the beginning of 2019. Today, all new textiles are patched directly with UHF transponders, for instance, as soon as items of laundry are replaced. UHF and HF readers remain in parallel operation until the changeover is complete.

All IT Development is Done In-House

"We have developed in-house software to work with RFID data in all our processes. Based on this, our own IT company 'TotalTex' was founded as a subsidiary of the textile services company. This company distributes the software solution 'DigiTex' throughout the entire laundry sector", reports Wildschütz and explains:

"As a computer scientist and programmer, I have recognized the potential of my own software. When the demands on the IT structure in the textile services company increased, we hired a programmer and started the project, which was then integrated into the 'Digi- Tex' solution. The software solution covers the areas of merchandise management, production and logistics. The hardware, RFID readers, antennas, and transponders are purchased from external partners."

Fully Automatic Sorting Plant Currently Under Construction

All items of laundry are captured at the points of incoming and outgoing goods. Workwear items are individually pulled and sorted via antennas integrated in the sorting tables. A display above the table informs the employee which washing program must be selected. Special articles from different customers can be processed together. Currently, a fully automatic sorting system is being set up, which registers laundry items via RFID and automatically sorts and merges them according to 20 pre-programmed criteria.

The RFID tags' recorded data indicate whether the laundry is sorted by employee, by size or by department for outgoing goods – depending on the customer's requirements. Finally, the cleaned laundry is provided with a banderole that informs the delivery driver where the goods have to be transported to.

UHF-Tagged Containers for Flat Linen

The flat linen is captured in whole containers – in UHF-tagged boxes. All containers are read at the points of incoming and outgoing goods. "The data is used to optimally control and plan our processes. Thus, the whereabouts of each individual piece of laundry can be documented and foreign items can be detected quickly and reliably. Washing cycles can be viewed transparently. In addition, the customer is provided with comprehensive data on circulation quantities and shelf life of the textiles," says Wildschütz.

Live Data via Web Portal

"We provide customers with access to a comprehensive web portal where the process data for each individual item can be called up live. This includes the localization of the laundry items and the number of cleaning cycles. Master data of employees, departments, and cabinet management are also listed. This offers the customer the possibility to register new employees independently via web portal and to provide them – with clothes already tagged by us – from the pool. The customer no longer has to order new workwear for new employees. Textiles from the customer's warehouse can thus be assigned to specific persons," explains Wildschütz.

Customers can also use the web portal to make their own evaluations of costs, departments, and employees.

Comprehensive Textile Controlling as Primary Benefit

"The main benefit is the high data transparency of each individual laundry item as well as the exact allocation to cost centers and departments. This transparency is becoming increasingly important and is demanded by customers. The textile services company benefits from the optimized logistics, as pre-sorting and goods removal are time-optimized and virtually error-free. There are fewer points of friction between customers and service providers because mishandling is reduced and replacement trips are avoided. Security with regard to foreign items is extremely important, and RFID eliminates manual errors and incorrect delivery," says Wildschütz.

The result: More efficient and secure processes. "The data situation ensures that shrinkage can be precisely localized and inventory processes are simplified. In the workwear sector in particular, there are competitive advantages – which also offer increased advertising effectiveness – compared to laundry companies that work without RFID technology," emphasizes the Managing Director of the textile services company.

Source: RFID & Wireless IoT Global, Special Edition Laundry 2020