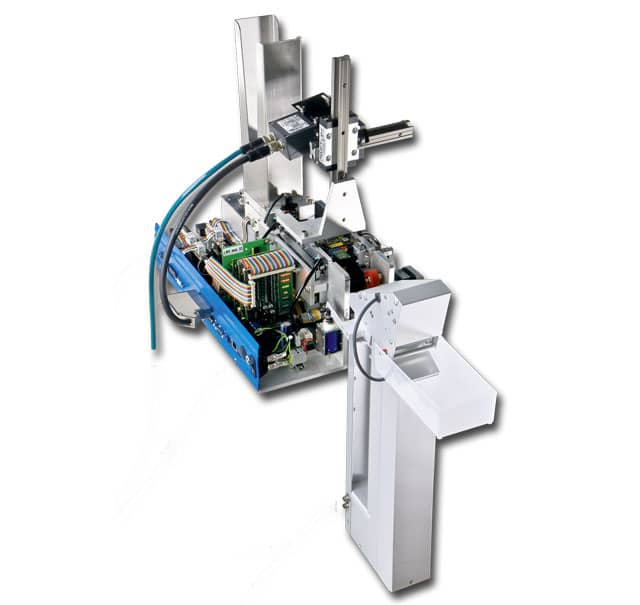

High-Tech Card Encoding Systems „MADE IN GERMANY”

New Challenges and Regional Ties

Rinas Gerätetechnik faces the challenges of the market and looks to the future with excitement and confidence. The high-tech company attaches great importance to regionality, high product quality and comprehensive customer support.

INTERVIEW WITH ARMIN RINAS

1. Many companies have suffered losses since the outbreak of the Covid-19 pandemic. How has your company coped with the crisis?

The crisis has, of course, also affected us. The fact that the event sector in particular has been severely restricted has also had an indirect knock-on impact on us. However, we have managed to get through the crisis without any state aid, via shorttime working allowances, for example.

All employees are still working hard and the whole team is curious to see how the market will develop in the future and what new challenges are waiting for us. One thing is certain: No matter what comes, we are ready.

2. Your company is located in a small community near Lake Constance and your team produces all its equipment at this location. How would you rate the company's local ties?

We deliver worldwide from a small town close to Lake Constance in southern Germany.

Our biggest sales market is currently Europe. I don't regard the fact that we are not located in an industrial metropolis as a disadvantage at all. On the contrary, we have nature and recreational opportunities right on our doorstep.

We are a locally rooted company and attach great importance to regionality. This is because all our equipment is produced at our site, in line with the motto "Made in Germany". We also source as many components as possible from regional manufacturers and we fabricate the required metal parts ourselves.

3. Keyword: Service and support. You ship worldwide – how quickly can you respond to maintenance requests?

In general, our equipment is sold directly through us, so we know exactly what the customer wants and only offer what we can implement.

Comprehensive support is not a problem because we have developed most of the parts ourselves.

In the case of defective electronics or a wear part, for example, our response time is on average less than three working days and if we have the relevant parts in stock, we can, as a rule, send the parts to the customer within one to two working days.

In principle, we recommend that our customers maintain a stock of appropriate small spare parts acquired at the time of machine purchase. This way, smaller maintenance jobs can be carried out independently under our guidance. This is particularly helpful if the customer is located outside Europe, thus eliminating potentially costly and time-consuming trips to the customer.