Demand for Semiconductors Strongly On the Rise!

At the beginning of the corona pandemic, the demand for chips in the automotive industry collapsed. Semiconductors already manufactured for the automotive industry were consequently sold to electronics manufacturers. With the recovery of the automotive industry, the demand for semiconductors has also picked up again. Currently, demand for semiconductors exceeds the quantities produced.

The current semiconductor shortage is expected to continue until at least mid-2022. For 2021, the World Semiconductor Trade Statistics (WSTS) forecasts an increase of eleven percent in the automotive industry alone. It takes several weeks to manufacture a semiconductor, and at least a year and a half to expand existing facilities. Bosch opened its new semiconductor plant in Dresden in May 2021. The semiconductor plant in Reutlingen, where Bosch produces 150 mm and 200 mm wafers, is still to be expanded in 2021. In total, more than 2.5 billion euros have been invested in semiconductor manufacturing since 2010. This sum will increase by a further 50 million euros with the expansion in Reutlingen.

Learn more about the complexity of semiconductor manufacturing and the global supply chain in the tech article "Global Semiconductor Shortage" in the latest "Smart City & Consumer IoT" issue of e-magazine RFID & Wireless IoT Global.

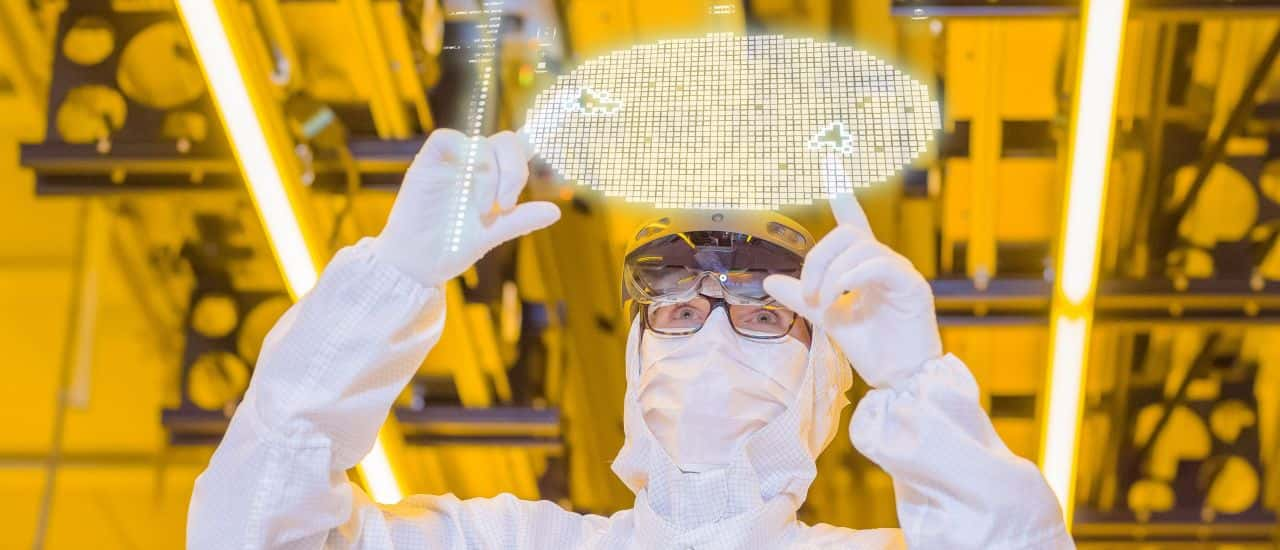

With the opening of the 300 mm Wafer Fab, Bosch is taking the next step towards a digitized future: "We are combining the Internet of Things with artificial intelligence – we are talking about AIoT," said Dr. Volkmar Denner, Chairman of the Board of Management of Robert Bosch GmbH. "Knowledge is created from data. In Dresden, we are opening our first AIoT factory: Fully networked, data-driven, self-optimized." Photo: Bosch

Germany as a Technology Site

Worldwide, there are only a few specialized sites that can perform different stages of semiconductor manufacturing. As a result, the supply chain relies on transportation between the globally dispersed sites and is particularly vulnerable to disruption. For this reason, Bosch chose to build its new semiconductor factory in Germany, right in the heart of Silicon Saxony, Europe's largest microelectronics cluster.

"It's about the resilience of global supply chains - and also about the fact that the European industry must not strive for self-sufficiency, nor must it be dependent on the economic and technological power of other regions of the world," emphasizes Dr. Volkmar Denner, Chairman of the Board of Management of Robert Bosch GmbH. The construction of a new chip factory cannot solve the problem on its own, but it is a contribution to the solution, according to the Chairman of Bosch.

Data glasses and augmented reality are just one part of Bosch's factory of the future: 300 mm wafer production is operated at the most advanced level with the help of fully networked AIoT, a digital twin and 5G capability. Photo: Bosch

Bosch Creates the Foundation for the Factory of the Future

With the help of a digital twin, planning for a future 5G infrastructure, and the combination of artificial intelligence and the Internet of Things (AIoT), Bosch in Dresden operates one of the most advanced semiconductor factories in the world. AI algorithms control production, immediately detect the smallest errors and automatically correct process deviations. In addition, smart augmented reality data glasses are used to further optimize the manufacturing facilities.

Bosch relies on 300mm manufacturing technology in Dresden. Up to 31,000 chips can be produced from one wafer. The factory area of 7,2000 m² accommodates 100 machines and systems, which are used to carry out the approximately 700 production steps in semiconductor manufacturing. When the plant opened in May 2021, 250 employees were responsible for operations; by the end of the expansion, this number is expected to increase to up to 700 employees.

Outlook 2022 and the Automotive Industry

In the future, the value of microelectronics installed in vehicles is expected to increase significantly. Several hundred semiconductors are installed per passenger car, and electric vehicles require twice that amount. "In 2016, every new vehicle worldwide had an average of just over nine chips from Bosch on board," explains Harald Kröger, CEO of Bosch. "In 2019, it was already more than 17. That represents a doubling within just a few years. We expect the strongest growth in the coming years in driver assistance systems, infotainment, and electric drive systems."