Data Controlled Banana Cultivation with RFID

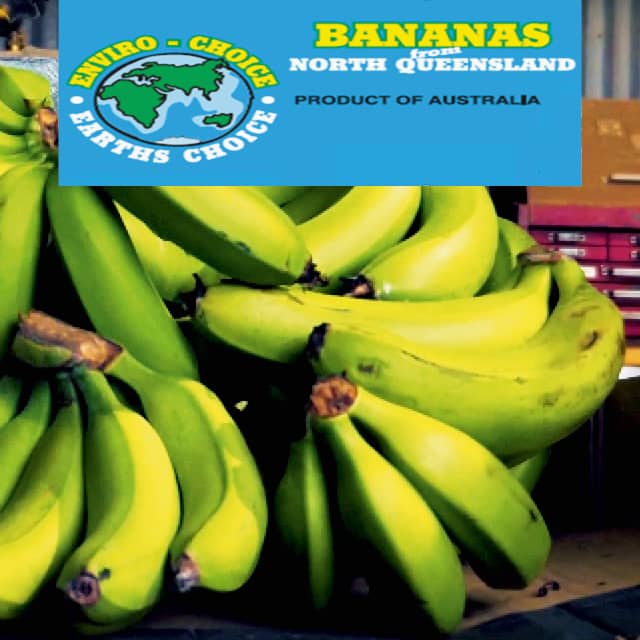

Bartle Frere Bananas is a family owned and operated company that has been in the banana growing business for over 30 years.

The company is the largest banana grower in Queensland, Australia, and uses RFID and sensor technology to monitor and control the growing, harvesting and supply chain of bananas.

Process Requirements

The bananas are grown on a ten-hectare plantation. Bananas that are ripe for harvesting should be able to be identified quickly. Devices used must be able to withstand the harsh environment on the banana plantation. Employees need small and lightweight RFID devices to be able to work hands-free and effectively on the plantation. Additional data such as water consumption, fertilizer use and nitrate pollution should be collected to make the plantation more sustainable.

Objectives of Bartle Frere Bananas

- Tracking every banana tree through cultivation, harvest and supply chain

- Making banana farming more sustainable

- Minimizing the impact of banana cultivation on the environment

- Quickly identifying ripe bananas for harvest

The Bartle Frere Bananas Solution

Bartle Frere Bananas tags each of the growing banana plants with an RFID tag and a unique identification number. The bananas can be tracked from the growing season, through the harvest period, to the point of sale. On the plantations, workers use mobile handheld scanners to read the RFID tags into the farm supply chain tracking system. The workers' hands remain free for other tasks.

During the harvest, ripe bananas can be located easily and quickly without having to search the ten-hectare area for ripe fruit - an enormous saving in time. After harvesting, the bananas are sorted and loaded onto pallets. The movement, temperature and GPS location of the containers can be tracked on their way to the sales floor.

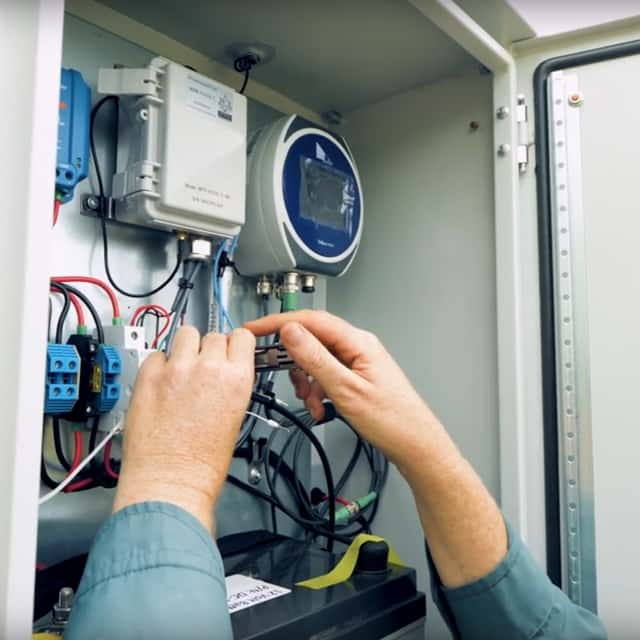

Weather data and water consumption are recorded on the plantation. Solar-powered, in-line nitrate sensors control fertilizer consumption, reducing nitrate runoff. GPS, RFID and sensor technology are used together to make banana cultivation more sustainable.

Technology Partner

Hardware & Software

- FEIG Electronic - HyWEAR compact

Advantages

- Bananas can be tracked throughout the supply chain, starting from cultivation.

- Harvest-ready fruit is easily and quickly located

- Employees' hands on the plantation are free for other tasks

- Water consumption and pesticide impact on the environment are reduced

Learn More

Questions? Get in contact with the editorial team!

Technologies

Application Fields