HF RFID for Identification of Crystalline Samples at EMBL

At the European Molecular Biology Laboratory (EMBL) more than 200,000 crystalline samples are processed per year, to research ingredients for new cancer drugs, among other things.

Continuous identification of each sample during the test series is ensured by labeling the sample holders with cryo-resistant HF RFID tags.

EMBL is a basic research institute founded in 1974 and is supported by 24 European countries, Israel and the associated member states Australia and Argentina. 85 independent working groups conduct research at a total of six locations in Europe.

Process Requirements

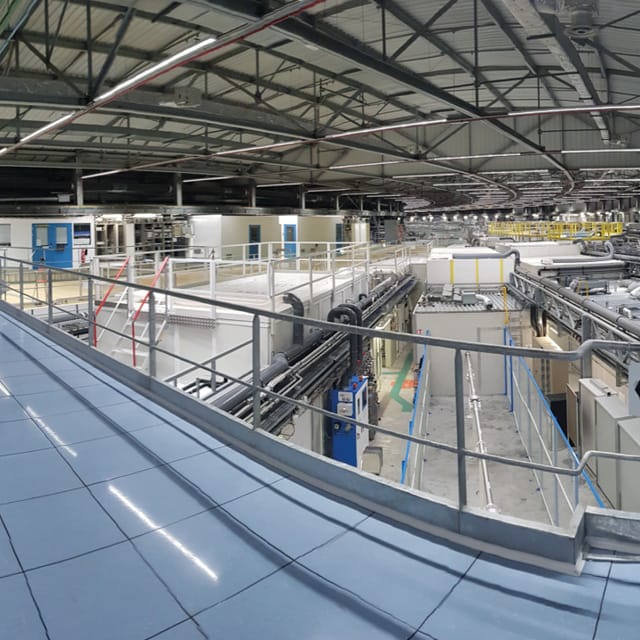

The ESRF's electron synchrotron, located in the immediate vicinity of the EMBL site in Grenoble, generates X-rays that are 100 billion times brighter than the X-rays used in hospitals to analyze the crystalline samples. The ESRF helps researchers worldwide to gain precise insights into the atomic and microscopic structure of the crystal samples.

Biological materials are studied in the beamlines of the electron synchrotron in order to promote the development of highly efficient medications, which, for example, should combat cancer more effectively. The samples are stored in analysis tubes at negative 196 degrees Celsius. Examinations and tests are partly carried out at room temperature. The temperature fluctuations are enormous and components used, such as sample containers and sample holders, must withstand more than 500 cycles in individual cases.

The increasing number of samples per year presented EMBL with the decision to develop an automated sample handling system in 2018.

Objectives

- Development of a highly automated, robot-supported sample handling process

- Use of technology that can withstand at least 500 temperature cycles with fluctuations of more than 200 degrees Celsius

Solution

A new sample holder standard in combination with a robot allows testing the growing number of samples without additional manual effort. The miniature HF RFID transponders used in the sample holders are manufactured in a patented process to ensure that they remain permanently robust against the high temperature fluctuations.

The tags are manufactured using the patented 'DBondTM' process, in which the IC is connected directly to the antenna. The elimination of an additional module and the direct connection increase the robustness of the tags. A hole with a diameter of six millimeters is available for inserting the tags into the sample holders.

The RFID identification of each individual sample holder enables the use of a robot for automated removal and re-storage of the sample holders from cryogenic storage.

Technology Partner

Advantages

- Highly automated, robot-supported sample handling realized

- Test performance guaranteed even with increasing number of samples

- Mix up of samples is eliminated

- The technology used ensures full function for at least 500 removal and re-storage cycles

Learn More

Questions? Get in contact with the editorial team!

Technologies

Application Fields