Reverse Logistics with RFID and RTLS

Founded in 2017, RevLogical LLC is a US-American Company specialized in reverse logistics for OS&D (over, short & damaged goods). Company headquarters are located in Kansas City, Missouri. RevLogical operates a transfer warehouse in Kansas City with a floor space of 30,000 square metres as well as seven stores of the ''Retail Rebel'' chain in the states of Kansas, Iowa and Missouri.

Overproduction from big-box retailers, damaged goods and returns from LTL (less-than-truckload) carriers are delivered to the transfer warehouse and identified. Relevant information on content and condition of products is registered. From the warehouse, products are distributed to the seven Retail Rebel stores and sold to customers.

The aim of the company is to improve inventory management in the transfer warehouse and decrease the time spent on processing deliveries. RevLogical requires a digital system to manage information of delivered goods and that enables the identification and localisation of pallets in the warehouse.

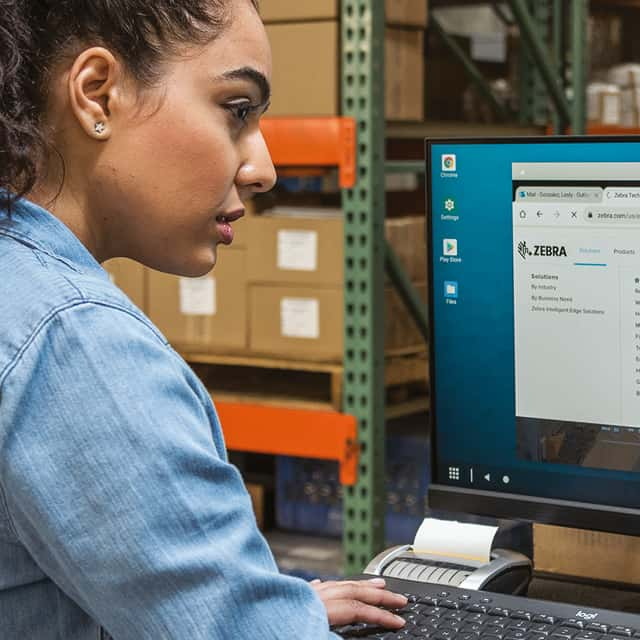

(Image Source: RevLogical, Zebra Technologies)

Process Requirements

RevLogical requires a solution that enables the scanning of barcodes from delivered OS&D goods as well as the labelling of pallets with additional information. Labelling is required to occur directly when receiving goods at the warehouse.

Following the reception of goods, pallets are stored in the warehouse until they are distributed to the stores. The company requires an inventory management solution that incorporates all product information in a central system and which enables the precise tracking of pallets in the warehouse.

Objectives of RevLogical

- Accelerating work processes when receiving goods: scanning of barcodes and applying identification labels with additional information

- Reducing time expenditure for the localization of pallets in the warehouse

The RevLogical Solution

RevLogical has implemented an RFID an RTLS system to locate and identify goods in the transfer warehouse. An RFID label is printed for every pallet when receiving shipments. These labels enable the correct identification and localization of every pallet in the warehouse.

Product pallets are identified directly when receiving shipments. Information on the condition and the number of goods is printed on an RFID label, which is applied onto the pallet.

When pallets are moved through the warehouse, the RFID labels are read by RFID and RTLS readers. The information encoded on the ICs of these labels is read and the pallet locations are recorded. The content and location of each pallet is displayed in a central software application.

Technology Partner

Hardware & Software

- Zebra Technologies – ATR7000 RTLS Reader

- Zebra Technologies – FX9600 Fixed RFID Reader

- Zebra Technologies – FX7500 Fixed RFID Reader

Advantages

- Accelerated work processes when receiving goods: scanning of barcodes and applying identification labels with additional information

- Reduced time expenditure for the localisation of pallets in the warehouse

- Efficiency improvements enable handling of larger shipments

Learn More

Questions? Get in contact with the editorial team!

Technologies

Application Fields