Transforming the Sake Supply Chain with UHF RFID

Sake brewery 'Asahi Shuzo' one of Japan's leading sake producers, supported and participated in a project of the Japanese Ministry of Economy, Trade and Industry (METI) to adopt RFID technology.

The aim of the project was to achieve end-to-end transparency throughout the supply chain from production to sales. The supply chain from the sake brewery to the liquor stores is tracked digitally and the flow of goods is visualized in real time.

The sake brewery 'Asahi Shuzo', headquartered in Yamaguchi, Japan, has three branches in Japan and one in Paris. In addition, the sake products are also sold in retail stores around the world. Asashi Shuzo was founded in 1948.

Process Requirements

Production of sake shrank to one-third of the peak production level in 2018. Marketing-related reasons as well as the decline in consumption and the distribution of sake products through unregulated retail channels were reasons for the decrease. Optimizing distribution – especially delivery – was therefore urgently necessary for brewers. The use of digital technologies is expected to transform distribution.

Objectives of Asahi Shuzo

- End-to-end visibility in real time across the entire supply chain

- Reduction of additional investments and working hours

- Tracking and tracing of goods throughout the supply chain

The Asahi Shuzo Solution

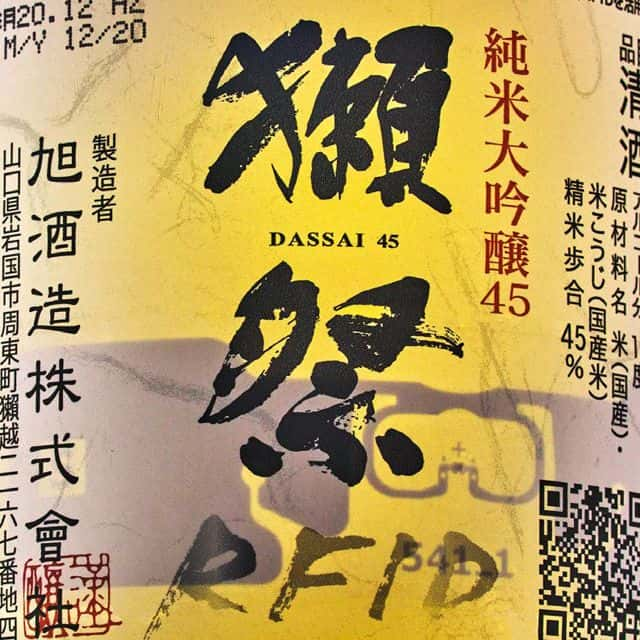

The RFID labels were to be integrated into the bottle labeling process with the existing bottle labeling machine without major investment and effort.

In addition to the integration of RFID labels on sake products, another challenge was that the IC chip could be damaged during application. This is due to the fact that the IC chip is subjected to a certain amount of pressure when the label is stretched to prevent wrinkles and when it is attached to the bottle by the crimping roller. To protect the chips during this process, Asashi Shuzo integrated inlays that were bonded to the IC chips using proprietary technology and production control methods.

Since UHF RFID is sensitive in the presence of liquids and glass, the RFID antenna had to be adjusted so that it could be read without problems even when attached to a sake bottle. After meticulous testing, a UHF RFID inlay was chosen that can be read from about three meters away when attached to a bottle.

After the RFID tags are attached to each individual bottle, the visualization of the supply chain begins. The aim is to use digital technology to track the supply chain from the brewery to the liquor stores so that the flow of goods is mapped in real time.

To facilitate tracking during the distribution process after shipment, Asahi Shuzo has associated the individual IDs of the 12 bottles with an RFID tag on the carton in which they are packaged. In this way, it is possible to track the distribution process of each bottle by simply reading the RFID tag on the carton, instead of identifying the RFID tag on all 12 bottles. In addition to the RFID tag on the carton, a QR code is also printed so that wholesalers and liquor stores that do not have RFID readers can read the QR code with a smartphone and perform the receiving and shipping process of the bottles.

In this way, breweries can now check whether their products are being properly delivered and sold in the designated retail channels. At the same time, consumers can now access information immediately, such as "When was this sake made?

Hardware & Software

- Avery Dennison Smartrac – Dogbone® RFID Inlay

Advantages

- Visualization of the supply chain in real time

- Consumers have instant access to product information

- Reduction of labor costs

- Increasing the efficiency of business operations

Learn More

Questions? Get in contact with the editorial team!

Technologies

Application Fields