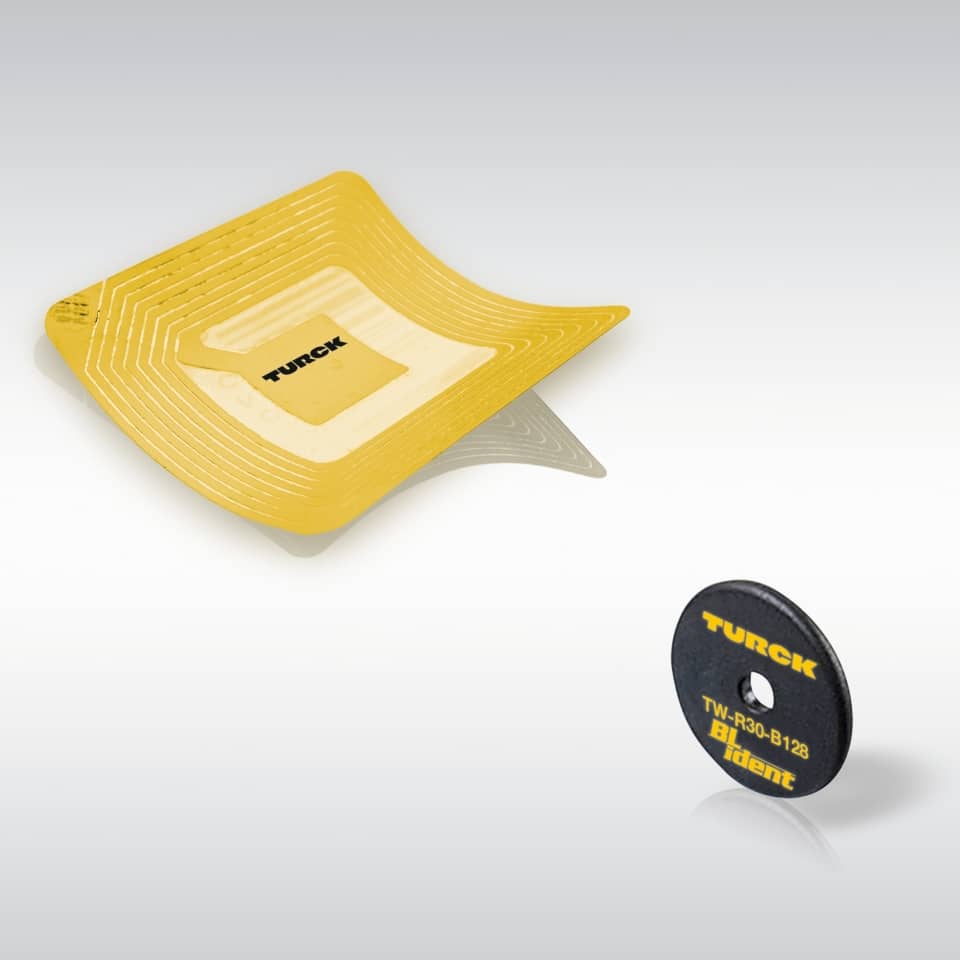

Checking the connections prevents tanks from being filled incorrectly!

- The identification of hose connections with the BL ident RFID system increases production safety and personnel protection

- HF RFID tags are integrated on the process connection and can be rotated freely

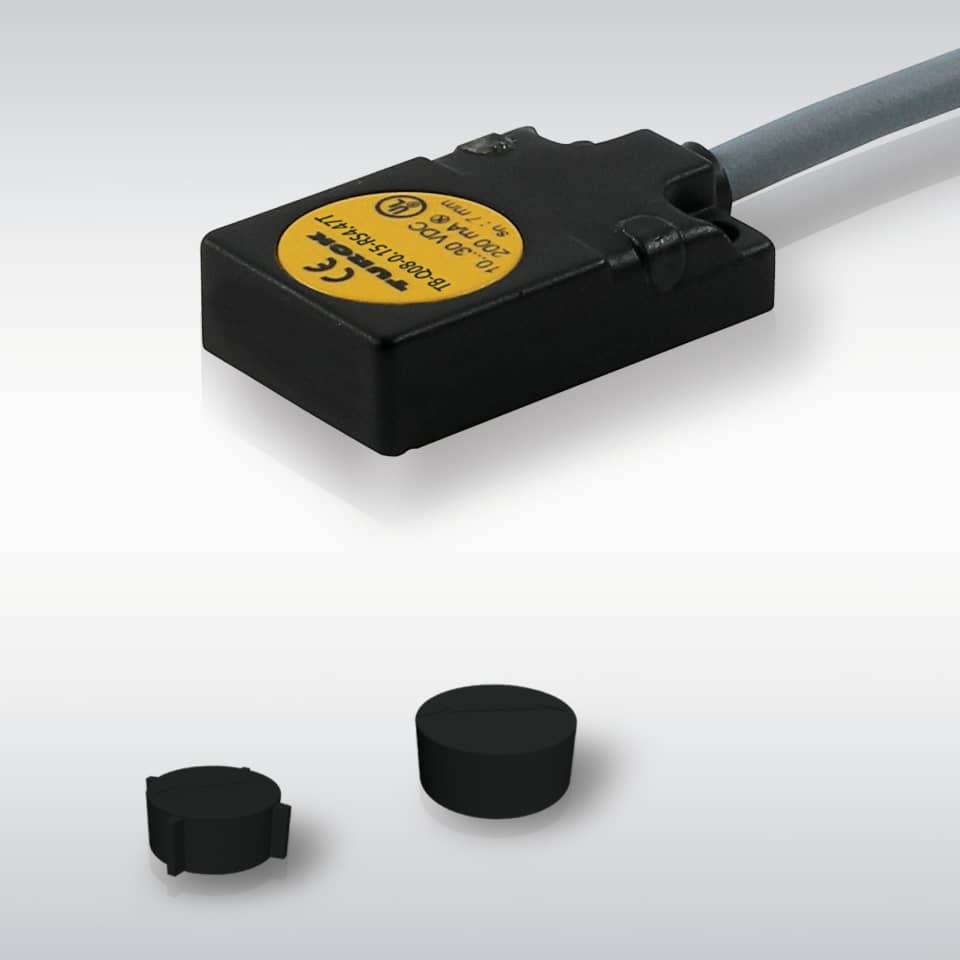

To guarantee the safety of personnel and to avoid tampering and errors, large hose connections (such as tank connections) can be checked using RFID technology. For this purpose, there is a freely rotatable metal component with integrated tag on the end of the hose.

When connecting the process connection, the tag always faces downwards and therefore hangs in front of the read/write head. In this way, the allocation of the connection is controlled and the possibility of filling a tank with the wrong medium is excluded.