RFID!

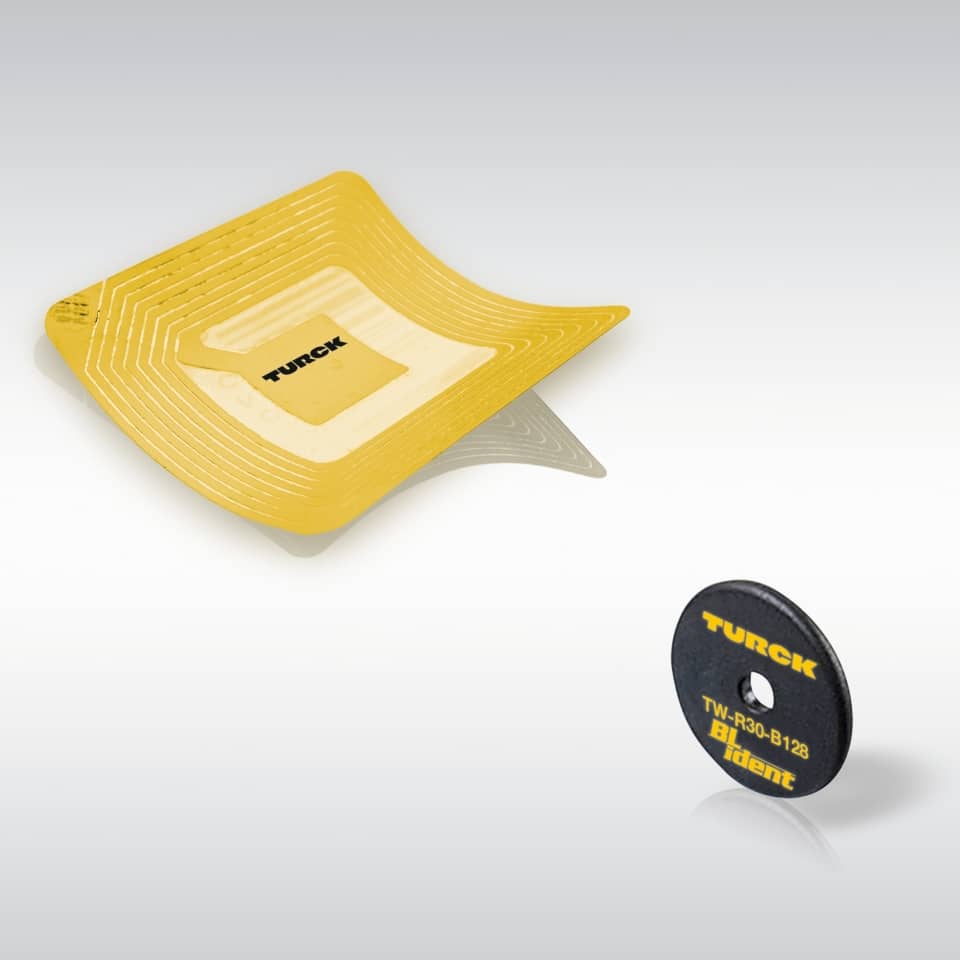

End-to-end tracking of incoming and outgoing goods, confirming automatically that the intended materials and tools are being used in production, or providing access points with increased security.

For such industrial tasks, RFID has proven itself as a powerful Auto-ID technology for Industry 4.0, with contactless transmission of large amounts of information, even over long distances, and easy connection to higher-level systems from PLC to ERP.

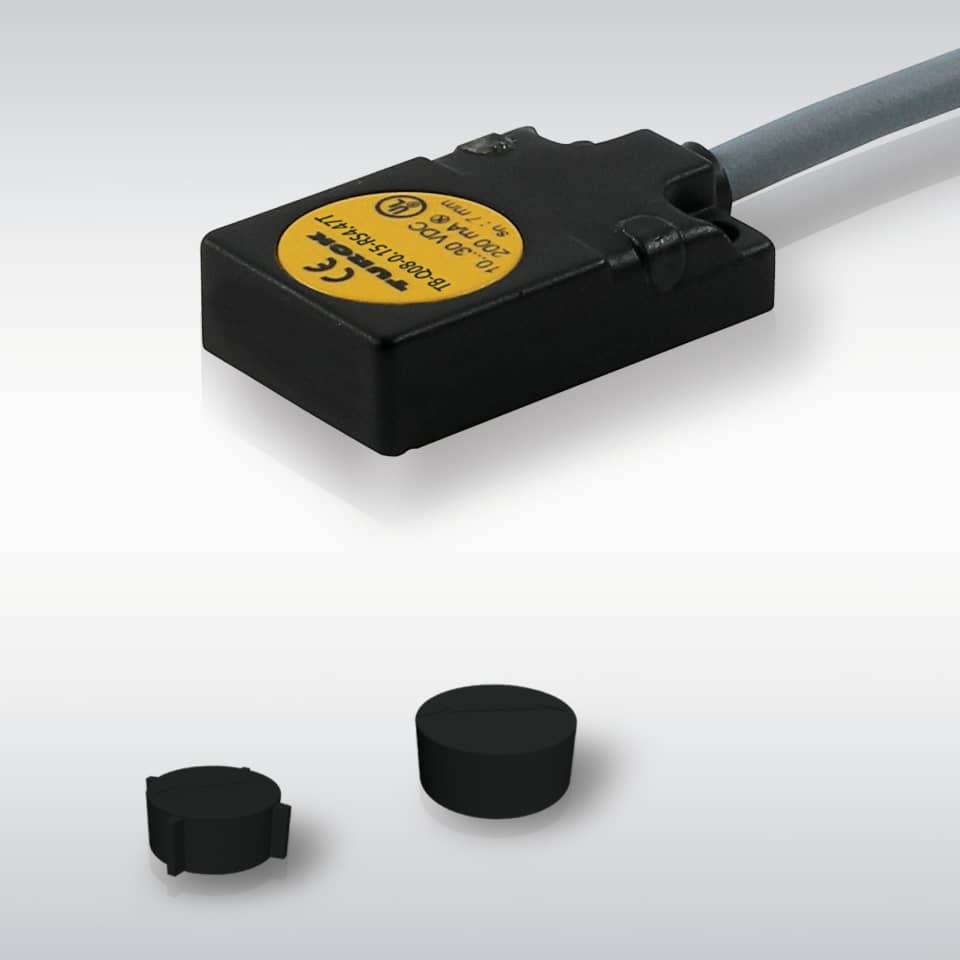

Choosing the right frequency band

HF technology (13.56 MHz) is an important driver of digital production processes, it is based on magnetic near-field communication. However, if higher ranges or bulk readings of 200 data carriers and more are required, users should opt for UHF technology (865...928 MHz).

Turck's modular RFID system BL ident enables the parallel operation of read/write heads in the HF and UHF range – and thanks to protection class IP67, this can also be done directly on site at the machine or plant. This allows consistently decentralized signal processing in the field.

Data transfer to higher-level systems

Communication in logistics and production plants today is divided into hierarchically structured levels. RFID readers with an Ethernet interface establish a direct exchange of information with higher-level systems, such as PLC, SCADA, MES and ERP or the cloud. Thus, goods movements are visible in real time, detected goods are matched with the database or, perhaps, automatic invoices are already created in the accounting software.

IIoT applications via OPC UA

The platform-independent communication standard OPC UA simplifies the integration of RFID solutions into PLC, MES, ERP or cloud systems. With the AutoID Companion Specification, it is also possible to exchange devices between Auto-Ident systems from different manufacturers.

Turck played a significant role in the development of the standard and has an own RFID interface with OPC UA server in its portfolio. For secure communication, the interface offers mixed operation of HF and UHF read/write heads.

With Integrators and the Right Middleware to Turnkey Applications

Especially for UHF projects, the know-how of system integrators pays off for companies. These specialists not only master the parameterization of read/write heads, for example to exclude interference with other devices, but also take over the installation of middleware. For the systems involved, it is in fact the middleware that makes the information on a data carrier usable - filtering and transmitting or visualizing it as required.

Since 2018, Turck also offers turnkey RFID complete solutions through its subsidiary Turck Vilant Systems. The RFID specialist has already realized more than 1,000 RFID system installations in 35 countries and increases the efficiency of all track-and-trace processes along the supply chain with reader systems, internally developed middleware and on-site service.