Zebra continues to aggressively innovate around real-time location systems!

While RFID is rising to the top of the “track-and-trace” pack, it’s far from the only technology option. Sometimes, it’s not even the best option. This is what you need to know.

In public safety, you hear the term “situational awareness” used quite often. Police, firefighters and military members are trained to know the location of people and assets at all times. They’re given technologies that significantly enhance their visibility of their surroundings. That’s because situational awareness is critical in defining the next-best action, enhancing proactive decision making and achieving desired outcomes safely and efficiently.

Like public safety professionals, those who work in manufacturing, warehousing, farm to table, transportation, logistics, retail and healthcare can all benefit from situational awareness. This includes athletes and field service technicians. However, they need a certain level of “location awareness” as it relates to critical assets in order to maintain the full situational awareness required to act fast when opportunities or issues arise.

For example, hospital staff need to be able to locate patient testing equipment such as drug infusion pumps and EKG machines within seconds during emergency triage situations, and IT teams need to be able to track equipment in server vaults and system operations control rooms to eliminate the risk of lost or misplaced equipment and identify immediately when equipment has been stolen or breached.

That is why Zebra continues to aggressively innovate around real-time location systems, or RTLS. This article is written by Kent Landry, Director, Location Solution Sales, North America, Zebra Technologies.

Data Becomes Most Valuable When It Is Viewable – and Actionable – In Real Time

Many organizations have been eager to increase the speed and agility of both individuals and teams to keep up with customer demand without compromising quality or safety for quite some time. In fact, retailers, warehouse operators, manufacturers, healthcare providers and others have been exploring ways in which they can use real-time location systems based on radio frequency (RFID), Wi-Fi, Ultra-Wideband (UWB), Bluetooth Low Energy and similar technologies for a few years now, with an uptick in RFID adoption specifically acknowledged in Zebra’s 2019 Intelligent Enterprise Index:

That is because supply chain-dependent organizations have, for years, acknowledged the need to implement more sustainable business models amidst labor shortages, increasing SKUs and instant fulfillment expectations. Though supply chains’ resiliency and efficiency are certainly being tested amidst heightened demand resulting from the COVID-19 outbreak, it was actually the rise of e-commerce earlier this century that spurred the uptick in RTLS investments and led us to predict the growth of RFID-based RTLS in 2020 specifically.

To paraphrase something my colleague Chris Schaefer wrote last year: "No business can afford to lose control over valuable assets, and going on a goose chase to locate misplaced items simply wastes resources. But maintaining asset visibility 24/7/365 does more than improve one’s bottom line; it can mitigate hazardous incidents, reduce liabilities and help save lives."

In my opinion, that’s the top reason why real-time location solutions are really having a moment – and why they will become even more of an implementation priority in the coming months for many organizations. Of course, recent events have only made the necessity of location solutions more evident tor anyone who needs accurate, real-time visibility into inventory, assets and staff as they move throughout the supply chain, within a facility, in the field or even on the field.

With RTLS, You Can See Everything…Even When You Don’t Have a Line of Sight

If you already have a barcoding system in place to track inventory movement and cameras to track people and equipment, you may be wondering “why do I need RFID or UWB or Bluetooth Low Energy?”

The short answer is that more advanced technologies such as RFID make every asset, whether a person, piece of equipment or inventory part more visible, connected and optimally utilized across operations. You can “see” where something is located in near-real-time without having to send someone to lay eyes on it to confirm.

Even more, RTLS technologies enable you to actively scan for, track, trace and immediately locate multiple tagged items at once using array readers – something that’s not currently possible with barcode technology.

The Modern Retail Collective recently demonstrated the potential use case for RFID-based RTLS technology in retail stores, and many hospitals are now using RFID to quickly find equipment that’s constantly on the move, such as beds, wheelchairs and IV stands. RTLS solutions can also help with safety goals. For example, Buenos Aires-based healthcare network Sanatorio Finochietto is using UHF RFID technology to view the locations and status of 80,000 pieces of clothing and linens as they are used, laundered and returned to their hospital to prevent cross-contamination issues.

We’re also seeing many automotive manufacturers in EMEA, in particular, adopt RFID-based technologies in order to automate parts receiving, put away and picking processes. They’re asking hundreds of suppliers to add RFID labels to parts and pallets in order to reduce the burden on workers, increase supplier accountability and improve inventory management and product performance tracking capabilities.

Yet, unattended track-and-trace solutions aren’t the only way RFID technology can be applied. RFID labels and handheld RFID readers can essentially replace any barcode-based system used today to identify inventory and equipment, ensuring visibility across all supply chain nodes.

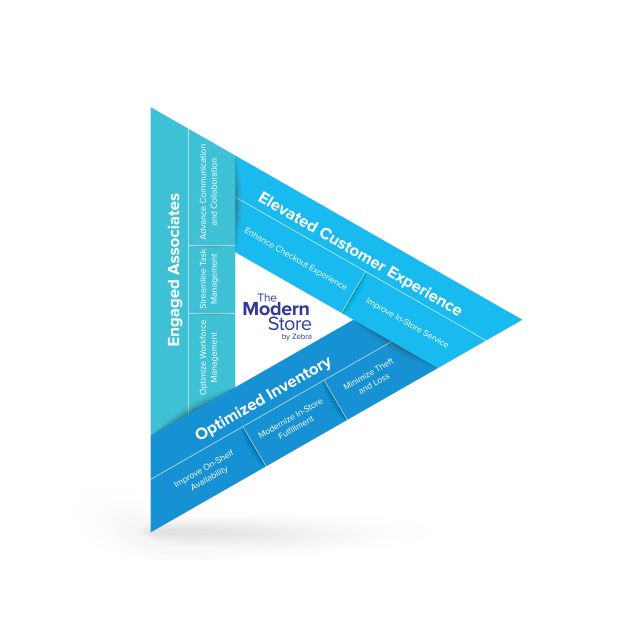

In fact, handheld RFID mobile computers that double as an inventory management tool and barcode-based mobile point-of-sale (POS) device continue to gain significant traction. Retailers are faced with the challenge of building a truly integrated shopping experience whereby the in-store, online and in-between (i.e. buy online, pickup in store) shopping experiences are seamlessly interconnected.

They need complete visibility into and control over their inventory at all potential fulfillment sites, and giving store associates a single RFID-enabled device that enables them to complete new inventory intake or RFID tagging and assist with returns management or customer checkout can be critical to achieving their goals. Plus, RFID is one of the technologies that has proven to deliver up to 99 percent accuracy in inventory track and trace.

How to Know Which RTLS Technologies Will Deliver the Best Return on Investment

Though I wish I could say that RFID reader X combined with RFID tag Y is the most effective track-and-trace solution for a specific workflow or industry, finding the right combination of location technologies for your needs just isn’t that cut and dry. If you look back at how “location awareness” technologies have evolved in recent years, you’ll notice two things:

- The rapid engineering advancements of track-and-trace technologies

- The expansion – or spread – of real-time location system portfolios by technology companies such as Zebra

Consider RFID: there are multiple flavors of passive and active sensors and technologies and a whole host of tagging and scanning solutions, each of which work in a different way to confirm the temperature or absolute location of the people, equipment and/or materials needed in order to complete a task or inform a decision at any given moment. There are even more variations of UWB, Bluetooth Low Energy, Wi-Fi and long-range sensing technologies engineered specifically to deliver up-to-the-minute digital views of your physical operations.

However, track and trace has become somewhat of a “team” sport over time, with companies such as Zebra working with customers and partners to tightly integrate together the right combination of location technologies for their individual business challenges and goals. Like many technology solutions today, there is no such thing as a “standard” RTLS architecture, mainly because each organization needs its location solution to yield a very specific type of asset intelligence or work within a very tailored workflow. There are also differences to consider in how indoor versus outdoor location solutions might work.

While passive RFID might be the best technology platform for IT asset tracking or high-value tool and equipment tracking – scenarios where you want to improve utilization and keep inventory and replacement costs down – it is very possible that a Wi-Fi-based RTLS would be recommended for medical equipment management.

UWB or WhereNet, both of which track active tags, might be the most effective technologies for tracking materials, production line progress and even people – anything constantly on the move. Then again, Bluetooth Low Energy might be recommended for people-tracking depending on the scenario (i.e. following shoppers in store via their smartphones, maintaining social and/or working distance standards and so on).

That being said, even drilling down to a specific industry or workflow doesn’t allow for us to recommend a “standard” RTLS solution. For example, a warehouse operator might need to utilize a combination of UWB and passive RFID to track forklifts and pallets while another warehouse operator finds that integrating both active and passive RFID technologies will enable workers to find freight faster and improve forklift utilization. And both of those warehouse operators may opt to utilize passive RFID tags, mobile readers and fixed readers to track IT assets used within their operations.

There are also several emerging use cases for real-time location solutions outside the industrial sectors that have traditionally embraced them. The NFL is certainly one: it uses active RFID to analyze athletes’ performances, improve training and optimize game strategies. But fleet managers in the utility, energy, public safety and transportation sectors are also finding RTLS increasingly valuable to the tracking, measurement and management of vehicle performance.

Then there’s the location engine, which typically uses multiple algorithms and technologies to provide an accurate and centralized view of location technologies such as beacons, sensors and receivers. Given how many different types of location technologies may be implemented in a single solution, not all location engines may be the right fit. The Zebra MotionWorks Enterprise platform, for example, can be deployed on-premises or in the cloud and is sold on a solution-quote basis, based on the size and capacity of the total RTLS solution. This is where discovery workshop sessions prove extremely valuable.

Once the RTLS solution provider understands the level of performance and accuracy you need, it will be easy to recommend the combination of technologies that will deliver the strongest return on investment (ROI). In fact, failing to conduct a cost-benefit analysis is one of the most common mistakes made by companies seeking to improve track-and-trace capabilities.

Kent Landry

Kent Landry currently leads Location Solution Sales for Zebra in North America. In this role, he is responsible for leading the sales and business development efforts for Real Time Location Systems (RTLS) across all industry verticals. Kent and his team provide sales, engineering and solution consulting to enable end users to positively impact workflows via RTLS solutions.