Zebra Leads Gartner's 2022 Magic Quadrant for Third Consecutive Year

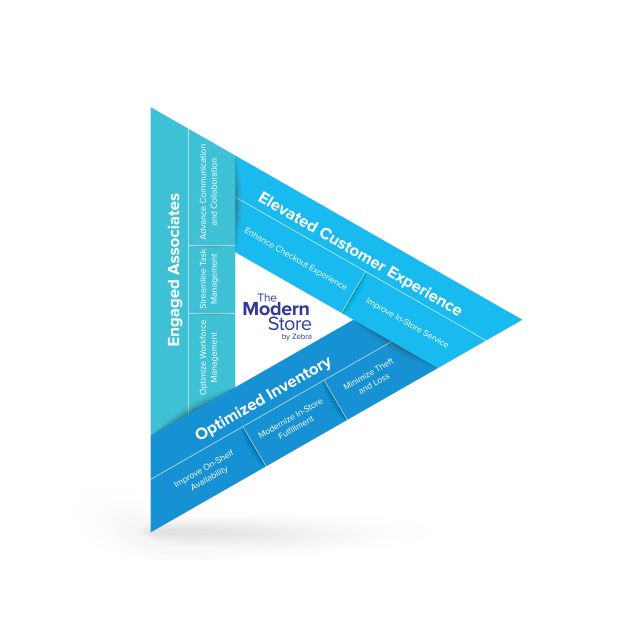

Zebra Technologies (NASDAQ: ZBRA) empowers organizations to capture and connect devices, workflows and employee movement in real time. With an award-winning portfolio of hardware, software and services, Zebra is driving the market in indoor location, according to Gartner, offering profitable and innovative products by international standards.

Leader in the Magic Quadrant in the Indoor Location Category

Zebra Technologies has been named a Leader in the Magic Quadrant by IT consulting firm Gartner for the third consecutive year. Magic Quadrant comprises a series of market research reports that evaluate the completeness of a vendor's vision and ability to execute. Leading vendors demonstrate a clear understanding of market needs, they are innovators and thought leaders, and they have well-articulated plans that customers and prospects can use to shape their infrastructures and strategies. They also have a presence in the top five geographic regions, consistent financial performance, and broad platform support.

Indoor localization with RFID & BLE

One of the challenges in indoor localization is determining not just the approximate location of boxes and the like in the warehouse or garments on the sales floor, but the exact one. For this purpose, Zebra offers a range of Bluetooth beacons and RFID tags that are attached to the goods. Depending on the application, the components are equipped differently; they can withstand chemicals, water, heat or noise, for example. Movement information can be tracked seamlessly. Localization accuracy is below 30 cm/ 12 inches.

Real-time Tracking of Industrial Trucks

Zebra found a customized localization solution for Toyota Material Handling, which manufactures forklifts and industrial trucks. At the plant where the trucks are manufactured, accurate tracking with UWB was not possible due to the large amount of noise - which interferes with UWB signals. Zebra applied more than 400 RFID tags to forklifts in the factory and integrated 60 RFID sensors at selected points on the factory floor.

The tags and sensors were adapted to the harsh environmental conditions. Existing APIs were used to install the MotionWorks Enterprise infrastructure, which views product orders and goods locations. Products and components transported on forklifts continuously generate movement and location history data. These can be read out by employees using a handheld device if the movement deviates from the planned route. An adjustment and optimization of the route can thus easily be made.