Optimizing Operations with Advanced RFID Technology

At a glance:

- PCB production with RFID

- Understanding the system structure

- RFID installation methods

- SMT and pasting methods

In a bold move towards enhancing efficiency and traceability, ReadFind IoT announces the integration of RFID solutions into its PCB production line. This strategic initiative aims to streamline operations and improve the overall manufacturing process. By leveraging advanced RFID technology, ReadFind IoT is set to revolutionize the traditional methods of PCB production.

Understanding the System Structure of RFID Integration

The system structure of RFID integration is integral to enhancing manufacturing processes. This integration involves components like the Field System, Handheld System, Interface System, and more. The Field System, including RFID readers along the production line, collects and writes RFID information and product details. Seamless interfacing with on-site servers ensures smooth data transfer, enhancing efficiency. The Handheld System aids in product verification and data binding, while the Interface System facilitates integration with MES and ERP platforms. Additional components like Equipment Monitoring and Distribution Systems further improve operational efficiency. Understanding this structure unlocks the potential of RFID integration, driving productivity in manufacturing operations.

Exploring RFID Installation Methods in Manufacturing

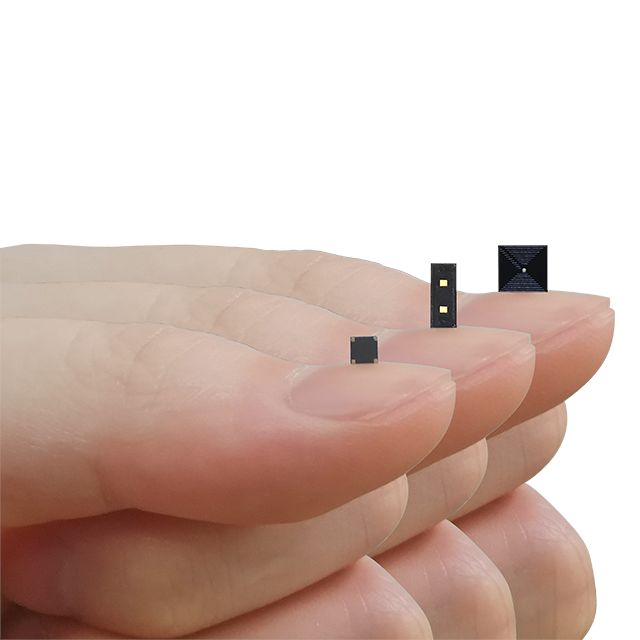

RFID installation methods significantly impact manufacturing efficiency. Two primary methods, SMT (Surface Mount Technology) mode and Paste mode, streamline production lines. SMT mode involves welding RFID ultra-micro tags onto PCB boards, ensuring traceability throughout the product cycle. Despite high-quality tag requirements and PCB reservations, it optimizes storage and maintenance. Conversely, Paste mode associates RFID tags with PCB serial numbers, offering cost-effective solutions. Understanding and implementing these methods enhance operational efficiency and product traceability in manufacturing.

Introducing the SMT Mode

SMT mode transforms RFID integration in manufacturing, delivering unmatched efficiency and space optimization. Ultra-micro labels seamlessly integrate into production lines, akin to ordinary component patches. The SMT-Production line import process optimizes efficiency and traceability through a series of meticulously orchestrated steps. Beginning with SMT placement from material tape, it ensures orderly installation and correlates PCB board serial numbers with RFID data, enhancing tracking accuracy. Subsequent stages, including ICT and Three-in-one testing, validate product integrity and incorporate standard defective RFID information. Label binding facilitates RFID information reading for product surface label application. Embracing the SMT-Production line import process empowers manufacturers with enhanced efficiency and precision throughout production.

Introducing Innovative Pasting Methods

Innovative pasting methods redefine RFID integration in manufacturing, enhancing efficiency and traceability. As an example, individual cases can be equipped with an RFID tag, elevating control and visibility in production. Post-PCB soldering, labels are seamlessly imported, binding ordinary barcodes and RFID tags. Subsequent processes effortlessly read and write tag information, supporting warehouse management and maintenance. Embracing these methods drives efficiency and precision in manufacturing operations.