Automated Intralogistics in Packaging Production

Sustainable packaging production and Pallet Tagging

Sustainability in Focus

Casimir Kast has made its company climate neutral since 2016 and also offers climate neutral products. In cooperation with ClimatePartner, the company's own CO2 emissions are calculated and offset via investments in certified climate protection projects. Of all materials used in the production process, in total 89 percent are now based on recycled materials.

Since the beginning of 2020, the company has also been certified in accordance with the FSSC 22000 hygiene standard, in addition to the DIN-ISO 9001 and the FSC standard that were already fulfilled. A well-known example of a climate-neutral product from 2021 is the GoGreen Packset commissioned by DHL.

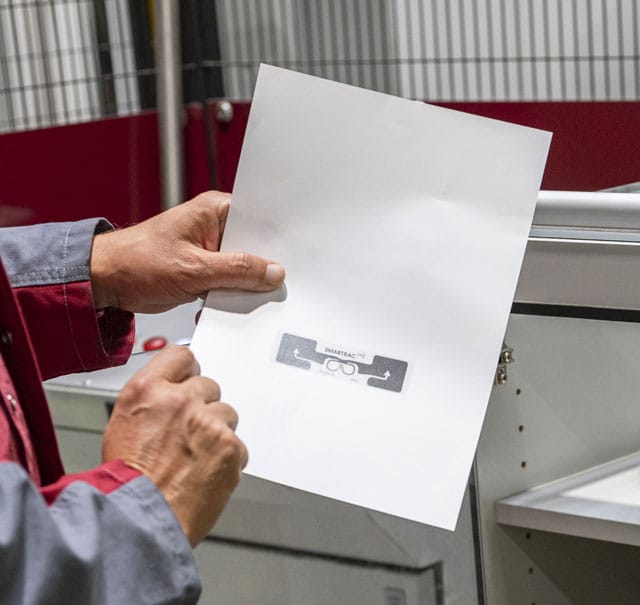

RFID readers are placed along the conveyor belt to read the information from the RFID pallet flags. They automatically capture how each pallet should be processed.

Production with 89 Percent Recycled Paper

The company specializes in the production of different types of offset laminated shipping or presentation packaging. For this purpose, the paper sheets are first printed with the customer's print image. The next step is to merge the sheets with the corrugated cardboard produced in-house. This is done inside a machine, "inline", where the corrugated board is first produced and then the sheets laminated onto the corrugated board.

In the next step, the packaging is given its shape on the die cutting machine, where it is punched out of the sheet in its final form. Next comes the distinction: Should adhesive dots be applied so that the packaging can be easily assembled later, or is it a ready-to-ship cut?

In accordance with this, either further internal processing is carried out on one of the adhesive machines or the packaging is sent directly to the internal shipping department. Along this entire route, the paper sheets are initially stacked and transported on pallets, followed by the finished packaging.

7,000 Pallet Flags Printed Per Month

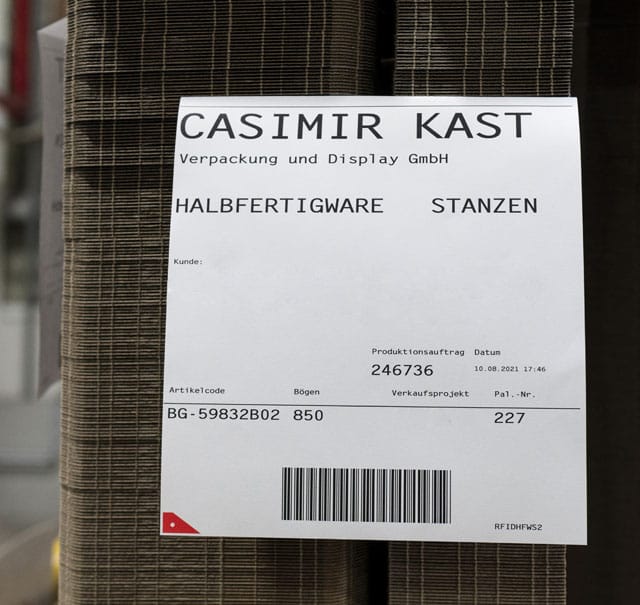

For each product range, at least two pallet flags are printed for unique identification. Casimir Kast uses Lexmark printers for this process, each of which has a tray for normal paper and one for RFID paper.

The printed pallet flags contain both RFID chips and a barcode, which in turn is used by freight carriers in the supply chain.

Between 7,000 and 8,000 pallet flags are printed each month. Via RFID-controlled intralogistics, orders are handled correctly and faulty production and returns are avoided.