OPC Foundation

OPC UA – Bridging the Gap from the Sensor to the Cloud and Back

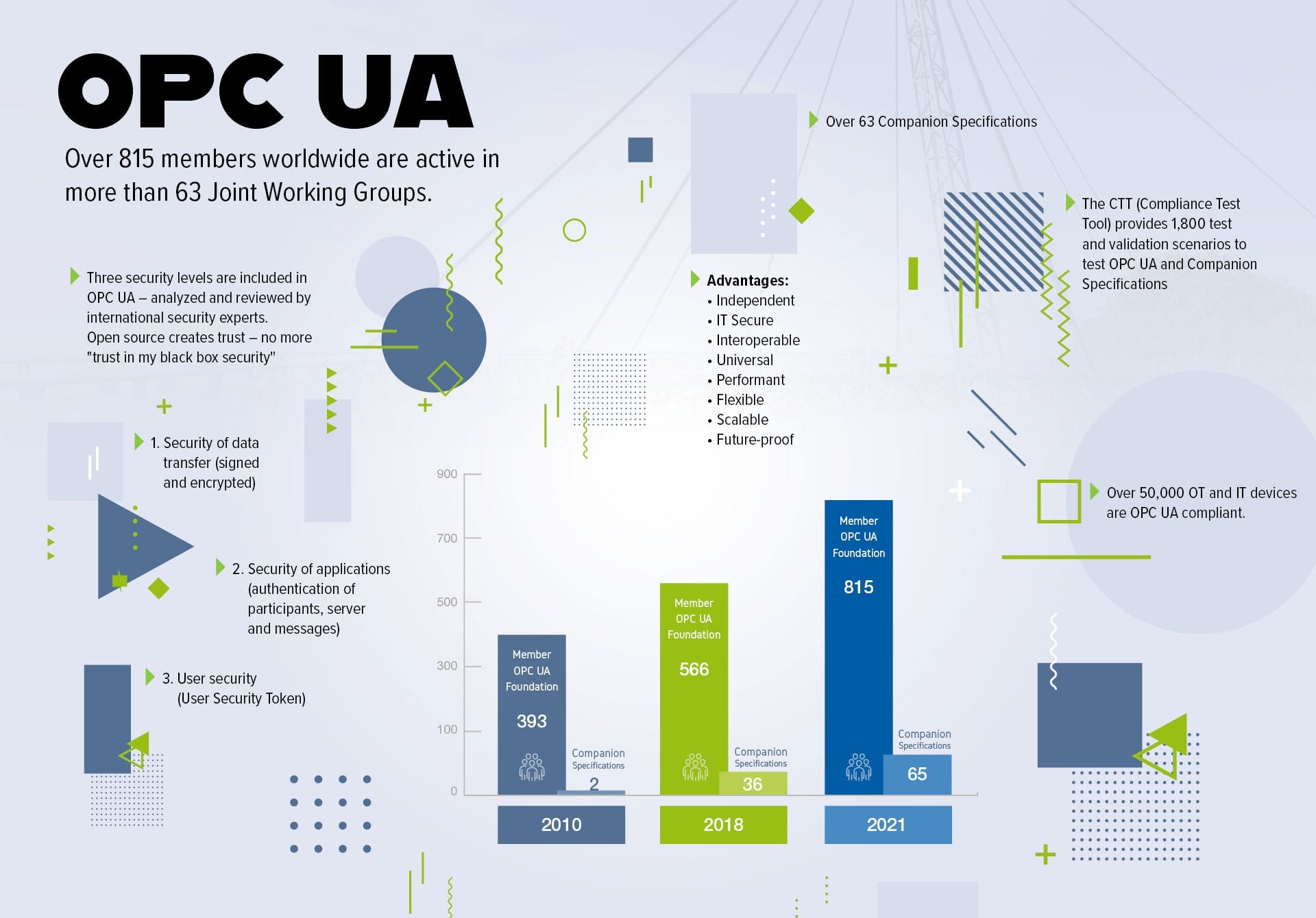

OPC UA – Open standard for industrial automation and interface between OT and IT

OPC UA – Open standard for industrial automation and interface between OT (Operational technology) and IT (Information technology). Equinor ASA and Renault Group are all using OPC UA. Stefan Hoppe, President of the OPC Foundation, explains the simplicity of implementing an information exchange across networks.

What's new at the OPC Foundation?