EUV Lithography in Semiconductor Manufacturing

System Upgrades and Development for the Future Semiconductor Market

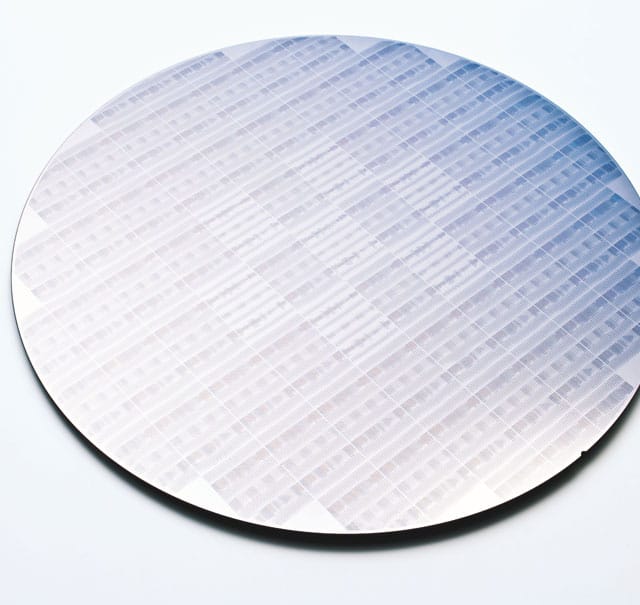

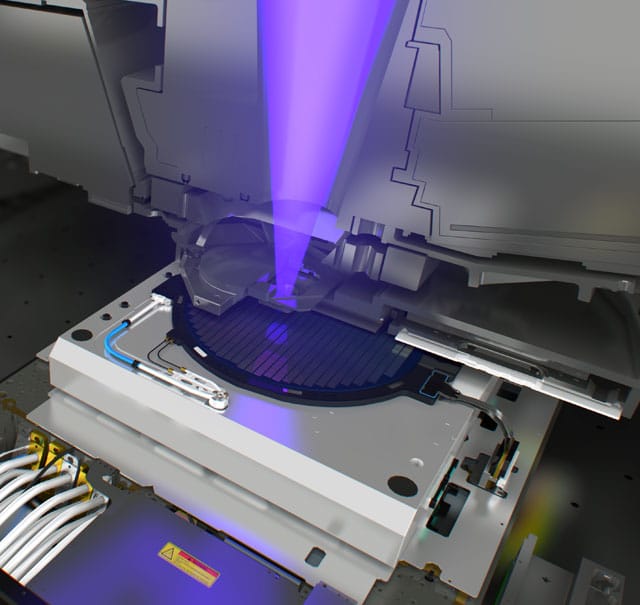

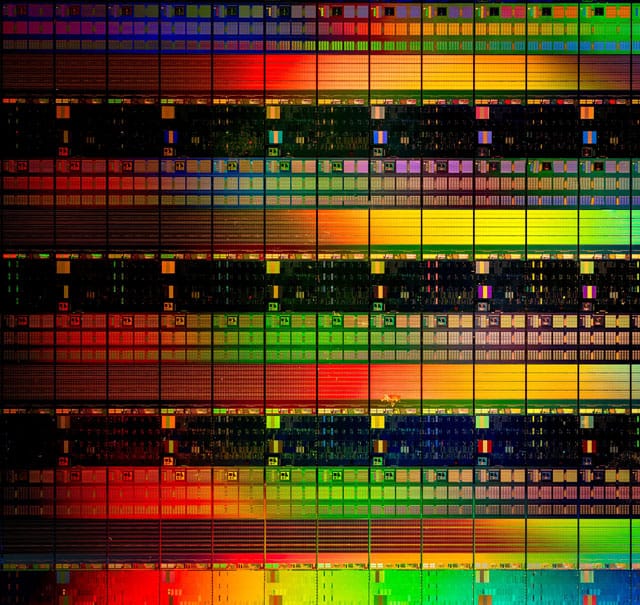

Not all of the dozens to hundreds of structures of a semiconductor must be printed using EUV technology. After EUV lithography, additional patterns and layers can be printed on the wafer by older machine generations. ASML's machines are modular, which simplifies the replacement of system components with newer modules.

11. What upgrades does ASML offer for existing systems?

Sander Hofman: ASML offers hardware and software upgrades. As defined in the roadmap, large initial deliveries of systems are executed and upgrades are offered approximately every couple of yearly quarters. This is an immense advantage of the modularity of the machines, which has proven to be a success factor for ASML over the years. ASML offers chip manufacturers a platform on which they can purchase the system with exactly the configurations needed for their specific chips. ASML regularly develops and offers upgrades. Upgrades can for example increase system productivity or offer more precision in mass production.

12. Do the upgrades involve downtime in production?

Hofman: The rollout of software is usually very easy and fast, while hardware upgrades can take days or weeks, depending on the type of upgrade. ASML's systems receive upgrades on a regular basis. It requires some downtime that is coordinated with the semiconductor manufacturers. This makes all the difference. As manufacturers run a highly automated fab, there are numerous different processes with multiple machines. Planned downtime ensures that disruption to production is kept to a minimum.

13. Do older generations of ASML's lithography systems also receive upgrades?

Hofman: Over 95 % of all systems ever manufactured by ASML are still in use today. The older systems are used in the production of chips with larger features and transistor sizes suitable for automotive or sensor applications. The market for semiconductors is booming in these application areas. We have systems in our product portfolio that are made specifically for these applications, with the service and upgrades that go with it. Some of our oldest systems are refurbished.

The number of transistors on microchips doubles about every few years. Systems like ASML's are constantly being developed and optimized to achieve even higher performance in chip manufacturing. EUV systems are key drivers for the production of the next generations of semiconductors.

14. How many EUV machines does ASML manufacture each year?

Hofman: In 2021, ASML shipped a total of 286 lithography systems, which included around 40 EUV systems. Currently there is a semiconductor shortage, with a huge demand driven by major trends such as 5G, AI and Big Data, Internet of Things, and autonomous driving. Production across ASML’s entire portfolio is set to increase. For EUV in particular, this means that a capacity of 55 systems is targeted for 2022. For the following year, ASML aims to produce 60 EUV systems.

15. What developments to you foresee for the semiconductor industry and ASML?

Hofman: As far as the development of the semiconductor industry and transistor sizes of chips are concerned, the answers can be found in the roadmaps of companies like Intel, TSMC and Samsung. These companies plan to shrink transistor sizes for the next decade and beyond. In part, this development is possible because ASML continues to fuel innovation with its EUV system.

ASML is already working on the next generation EUV platform, which will offer an even finer resolution. Mass production is expected to start in 2025. The supply chain is working actively to provide all components and modules that will come together in the ASML cleanroom in Veldhoven to build the first machine. The shrinking of transistor sizes is progressing rapidly and there is the industry appetite for it. There is chip in everything now, more so than ever before. There has also been an increase in all kinds of automotive solutions and sensor technology. The chip industry is booming, and we stand to offer the tools to push innovation forward.

16. How is ASML preparing for the changes in the chip industry?

Hofman: Crucially, if you look at the semiconductor market, there is a massive boom right now. Total industry sales are currently around $550 billion, and forecasts suggest that this could grow to $1 trillion by the end of the decade. ASML is currently expanding its production capacity. More space is being used and more employees are being hired to produce more machines faster. New cleanrooms are being built. This is an ongoing trend that can also be seen among ASML's strategic partners and suppliers.

Together, we are working on the next generation of lithography systems, while we’re also innovating the current generations. In my opinion, these are exciting times. We are entering an era where the semiconductor industry is at the center of a tremendous amount of innovation that will move the world forward. And hopefully it will help solve some of the problems we are dealing with as humanity, like climate change, access to healthcare, and education equality. Technology can help address these challenges in ways that have never before been possible.