Major Canadian Component Manufacturer Relies on RFID & RTLS

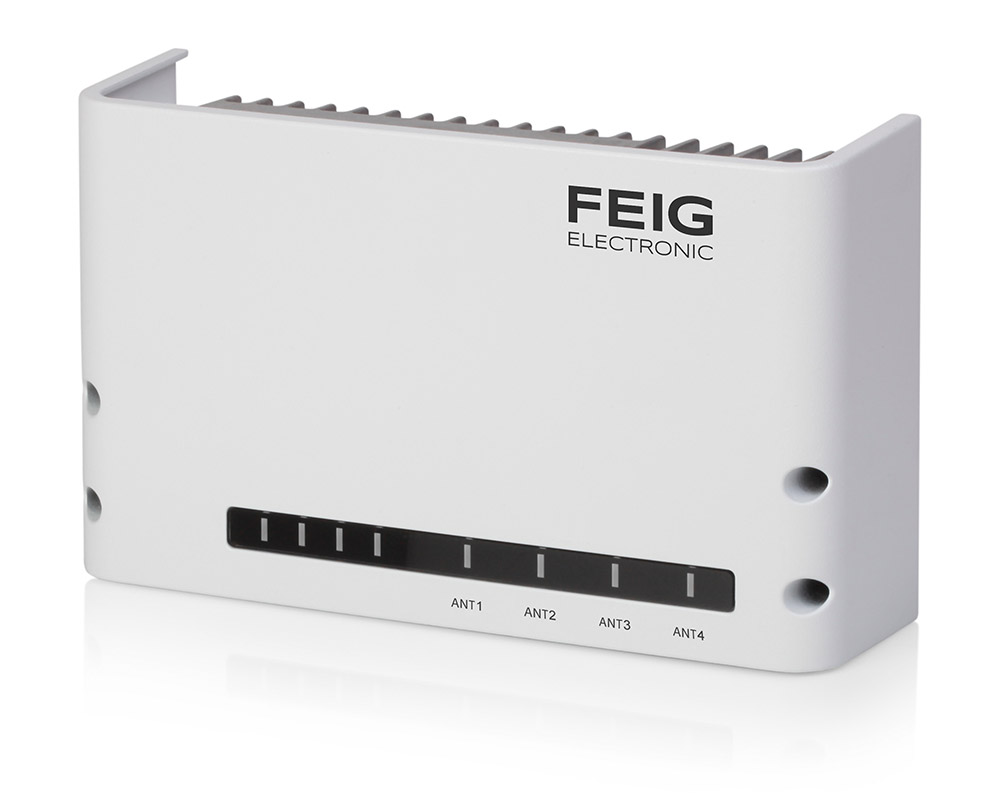

TORO Aluminium and UHF RFID Toro Aluminium has been using RFID transponders, UHF ceiling antennas and RFID handhelds to label and identify products in the production of prefabricated aluminum components since 2023. Production, interim storage, outgoing goods and the after-sales area are all automated. Windows and doors can be clearly identified and localized without contact. As a result, automation, data transparency and the degree of digitalization are increased. Success Story powered by: the Think WIOT Group, RFID Canada, FEIG and Times-7.