Production and Software Solutions for RFID Tag Manufacturing!

Mühlbauer was founded in 1981. In 1995, the first RFID inlay production solution was developed. Since then, the company has developed into a technology partner for the smart card, ePassport, RFID smart label and flexible solar cell sectors. Other business areas include microchip sorting, carrier tape systems, and automation, marking and traceability systems. Mühlbauer is the only company worldwide that supports all process steps in the production of complete RFID tags and labels.

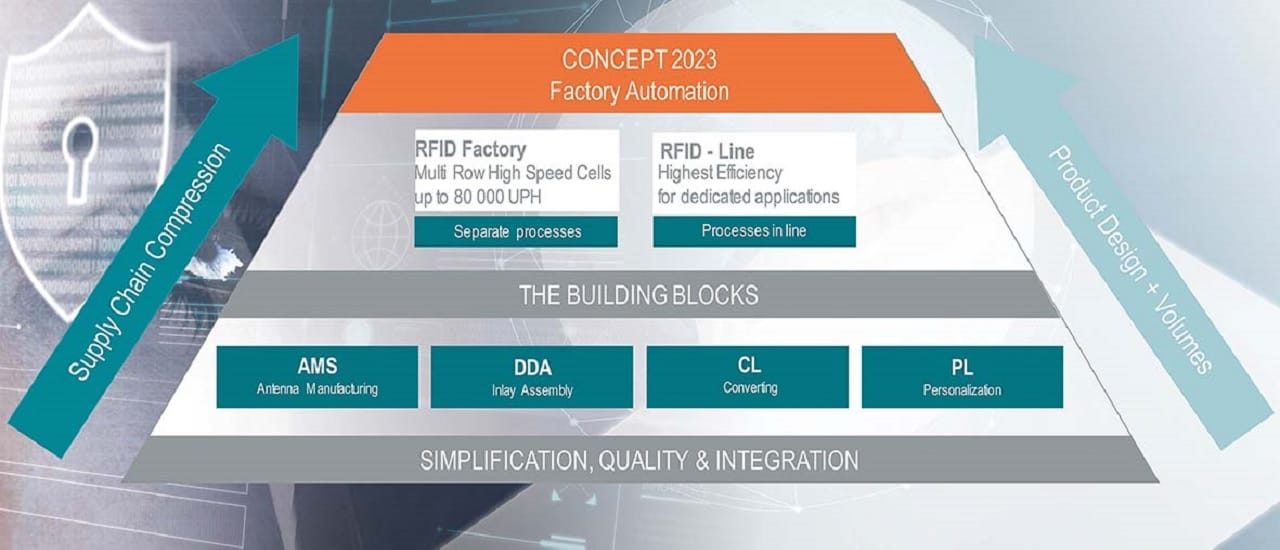

Production Equipment for the RFID Factory

Each machine is designed for a specific process step in the production of an RFID tag or label. All systems are modular, what facilitates the upgrade for higher production volumes.

Antenna Production

Two systems are available for antenna production: the Antenna Cutting System (ACS) and the Antenna Printing System (APS). With the ACS, antennas are milled from a PET aluminum laminate as a raw material. The APS prints antennas on paper using copper nano ink. Both technologies were developed for waste-free antenna production without harmful chemicals. The etching of antennas is no longer necessary.

Chip-Attach Technology

The RFID inlay production lines are used to place chips on the antenna substrate and to produce inlays for smart labels and contactless cards. The latest DDA 80000 system achieves a throughput of 80000 chips per hour. All systems have an integrated test unit and a bad marker. High production quality is ensured.

Conversion

In the converting line, the RFID inlay is laminated with a face and bottom liner, the top and bottom material, and then die-cut. A wide product variety of RFID tags up to luggage tags, metal tags, pet ear tags, paper tickets and hang tags can be realized.

Personalization

In the final production step, the RFID tag or label is personalized with chip encoding, printing and verification. Each label is tested for functionality and print quality. License-free encoding offers high flexibility for all encoding formats.

Software for the RFID Factory in Industry 4.0

The MB PALAMAX® is Mühlbauer's software system for Industry 4.0. Production data is recorded in real time. This includes overall plant effectiveness, yield, performance, and availability. The data is visualized as interactive diagrams and summarized in reports. Process and material planning is optimized. Inlays are produced more cost-effectively.

Contact the experts at Mühlbauer and to learn more about the production and software solutions for RFID Smart Factories!