How to Make Routine but Crucial Aircraft In-Cabin Checks in Less Time

Aircraft maintenance processes are crucial to flight safety. They are also time-consuming and demand large personnel resources. Every item in the aircraft needed a visual check. Are all oxygen masks in place? Is a life-vest present underneath each seat? Is the aircraft inventory still complete? The airliner was challenged to optimise this process without compromising the quality or completeness of any routine maintenance check. Read how the RFID solution from Brady helped the airliner to answer this challenge.

Solution: Scan Multiple Items at Once with RFID

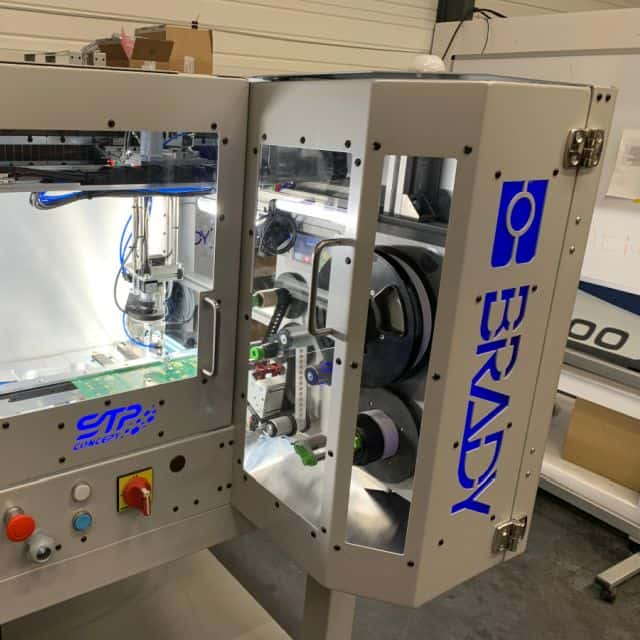

Brady offered a complete RFID solution to solve its customer’s challenge by making every in-cabin item visible, without the need for a visual confirmation.

Brady offered its extremely lightweight RFID Air Labels to identify most of the assets on board. The remaining metal assets were labelled with specialised on-metal RFID labels. These labels circumvent the laws of Farraday by equipping an isolation layer that allows the sending and receiving of ETSI-compliant RFID signals.

In addition, Brady offered powerful RFID scanners that can activate the labels, even when hidden in lockers, blocked by seats or otherwise concealed. On each scanner, a custom developed app was installed to perfectly fit the new technology in the customer’s existing processes. When scanning, maintenance crews do not only get an instant aircraft inventory, they can also see items highlighted for preventive maintenance or replacement. The app also allows verification that every item is in its assigned space.

Results: 10 Times Faster In-Cabin Aircraft Checks

Aircraft maintenance crews can now scan the area against an inventory list, rather than having to find and visually confirm every item. This creates a huge difference in operational speed, with effects on the availability of personnel and aircraft.

Brady's customer said mechanics now spend 90% less time on routine, periodical in-cabin maintenance tasks. These include checking data on life vests, oxygen generators and masks. A single specialist is all it still takes to get an aircraft checked. This also helps solve specialist availability issues at any of the airliners 130 destinations.

Discover more about lightest heavy-duty RFID solutions for aerospace!