Improving Efficiency and Cost Management!

Like most businesses these days, the automotive industry is affected by competition, the impact of the pandemic and the consequent need to stay profitable.

In this new contactless environment, the ability to digitize and connect the entire supply chain making information captured in real time visible and actionable can have a huge positive effect on costs and thus profitability. While most manufacturing and logistics businesses have some sort of automated inventory system and/or barcode technology in place, is it enough?

Article written by FEIG Electronic.

The more competition heats up, the more need there is for speed and efficiency. While a tight market may seem like the wrong time to spend money on internal systems, it is exactly the right time to reevaluate the effectiveness of existing systems and look for ways to improve.

RFID is reducing costs and improving accuracy and profitability for automotive businesses. Maybe it’s time to look at how improving processes with RFID or IoT technology can improved your business results.

RFID Integrates with Existing Barcode Systems

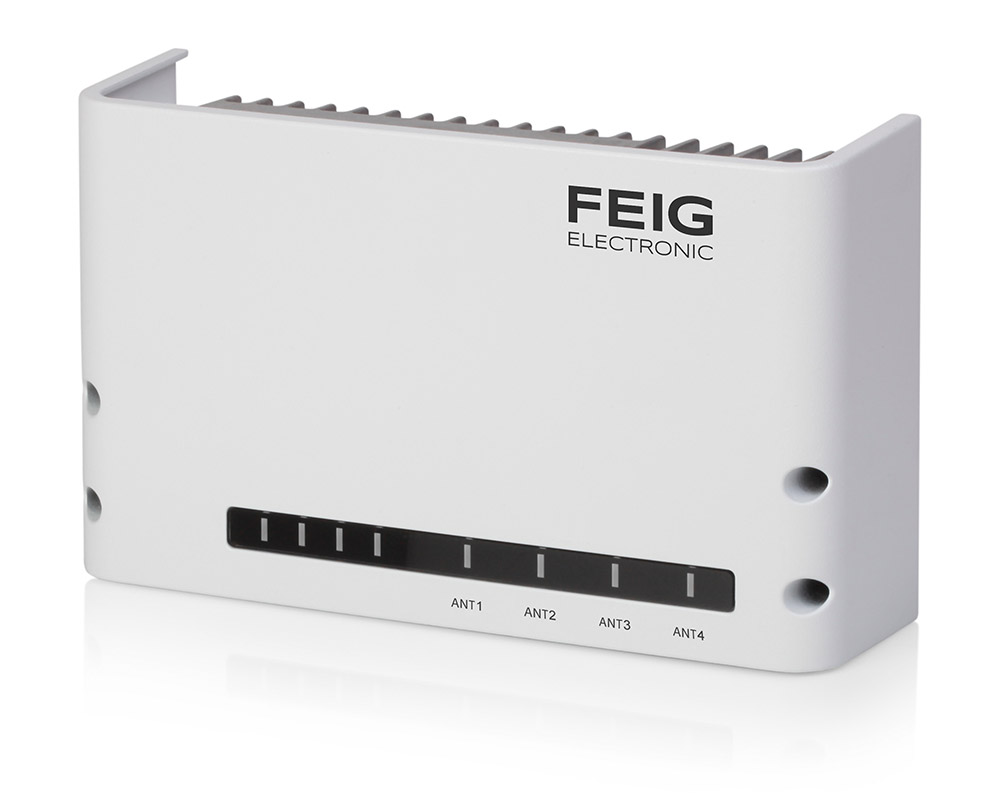

The great thing about RFID is that you can build on the investment you’ve already made in barcode technology. For example, if you have existing barcode systems, FEIG’s HyWEAR wearable is a hands-free hybrid that reads barcodes and RFID. With both hands free, employees work more efficiently, and the tones produced by the device offer auditory clues to accuracy.

RFID systems can monitor incoming and outgoing shipments, expedite picking and packing and facilitate sequencing e-Kanban and refill control, integrating with your existing systems and software.

Where the Rubber Meets the Road

A Brazilian automotive parts manufacturer that supplies bumpers for cars built in Brazil implemented RFID, replacing manual systems. Because they could plan for production, they saved 6 percent on raw materials. RFID has a unique code for every item, so they were able to quickly locate products in stock. They achieved 100 percent accuracy in order picking and shipping processes and reduced delivery errors by 95 percent.

What Can RFID Do for You?

- Real-time tracking of assets and inventory. Attaching an RFID tag to eachtool and part in your warehouse, you know where every element is. You lose no time searching for missing equipment or inventory. With RFID, you have at your fingertips exact knowledge of what you have and what you need to order. Use FEIG UHF gate solutions for efficiency, transparency and safety for incoming and outgoing shipments.

- Optimize workflow. RFID automates workflows from beginning to end. Incoming and outgoing shipments track effortlessly using UHF gate solutions, providing efficiency, transparency and safety. Automatic RFID tracking is highly accurate, so you minimize reading errors. Picking and packing using the hyWEAR family of scanners, hands are free and the device signals whether the picked item is correct.

- Reduce inventory for e-KanBan. When you know exactly what you have, what is running out and what you need to order, you keep your inventory at a minimum, yet still have what you need when and where you need it. FEIG LRU and MRU RFID detection systems directly control material retrieval.

- Improve resource utilization. RFID gives you the power to enhance your workforce. Inventory picking becomes an efficient process instead of wasted manpower.

The one thing we can count on is change – 2020 is a clear example. No one could have predicted the impact the pandemic would have on our lives and businesses. Implementing RFID into your automotive manufacturing and warehouse operations gives you the tools to stay agile and flexible for whatever comes next.

For more than 50 years, FEIG ELECTRONIC is a development partner and specialist in contactless Identification (RFID), electronic control systems, traffic sensor systems and payment terminals. Based in Weilburg, Germany and with a workforce of around 400, the company contributes to advancements in technology with innovative solutions for a wide range of applications and industries. Do not hesitate to contact us! We are at your disposal.