Improve your Logistics Processes with Scanners, RFID Readers and Wearables.

When you need more capability than barcode technology can give, FEIG offers a large portfolio of stationary RFID readers to take you to the next level. Mobile barcode scanners, RFID scanners and wearables from FEIG are easy to configure and can be integrated into any logistics process without the need for IT support.

Typical applications are incoming and outgoing shipments, picking and packing, e-kanban and refill control.

Smart Auto ID Solutions for Your Logistics Needs

Stationary barcode, mobile barcode and RFID readers are effective for a wide range of logistics applications, coordinating and improving your processes.

Incoming and Outgoing Shipments

Optimize performance for incoming and outgoing shipments

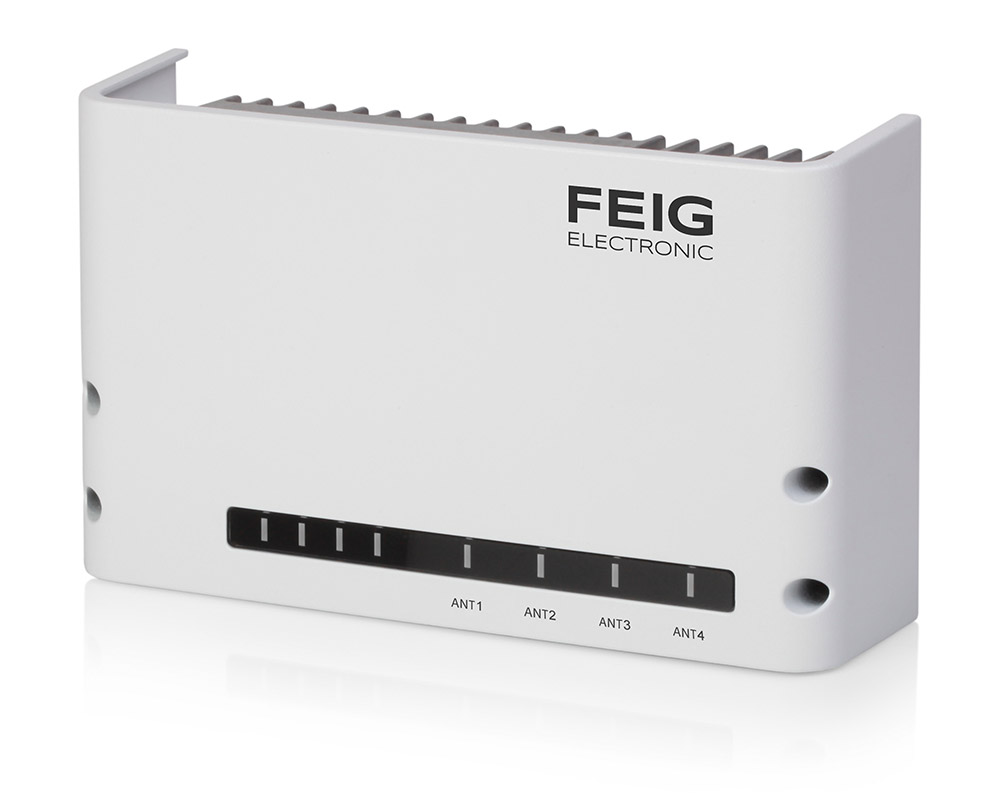

FEIG UHF gate solutions offer efficiency, transparency and safety in your product flow. They enable reliable bulk detection of large numbers of RFID tags during incoming and outgoing processes.

FEIG readers and antennas are highly accurate, so they minimize technology-related errors. During the read, they register the individual tags and, depending on how they’re set up, provide additional directional information to ERP systems.

FEIG products recommended for incoming and outgoing shipments:

- LRU1002 UHF reader

- LRU500i UHF reader with integrated antenna

- ANT.U290/290 UHF antenna

Picking and Packing

Picking and sequencing

Picking and sequencing processes have to be fast and accurate. For these applications, FEIG offers various stationary and mobile products that can be used singly or together. They provide the efficiency you need whether you work with 1D or 2D barcode, RFID or a combination of both.

When you consider mobile devices, the hyWEAR family of wearable scanners offers enormous advantages.

- Having both hands free for work accelerates processes by up to four seconds per scan.

- Signal transmitters such as different-colored LEDs, buzzers and vibrating alarms intuitively integrate employees into the process. The sounds immediately and clearly signal whether or not the picked item is correct.

- With state-of-the-art communication interfaces such as Bluetooth and WLAN, FEIG products are flexible and easily connected to existing infrastructure.

FEIG products recommended for picking and sequencing:

- HyWEAR compact RFID barcode wearables

- ECCO+ RFID Barcode scanner

- SCANNDYbasic Barcode scanner

Picking stations and packing points

FEIG offers a wide range of stationary HF and UHF RFID sensing devices for picking stations and packing locations, so it’s likely we have the right product for your needs.

FEIG products have a very high bulk detection speed. They feature trouble-free operation for multiple detection devices in the same frequency range. Parallel operation in dense reader mode offers the same fast, accurate operation. In addition, FEIG products offer dynamically controllable read ranges.

A wide range of antennas and commonly integrated interfaces offer flexible connection to existing systems for picking stations and packing points.

FEIG products recommended for picking stations and packing points:

- SPAD.U UHF Desktop Reader

- MRU102 UHF Universal Reader

- LRU1002 UHF Reader

- SCANNDYgun Barcode scanner

E-KanBan and Refill Control

Automatic material retrieval and refill control

Separate processes in the production cycle have to be coordinated for the right material to be ready at the right time in the right place. Control of the route train plays an essential role in maximum efficiency. Manual methods such as collecting cards or empty containers are time-consuming, error-prone, and can lead to production interruptions.

With the LRU and MRU product series, FEIG offers RFID detection systems that directly control material retrieval. FEIG systems detect small load carriers marked with RFID transponders when they are placed on the empty container sink and automatically generate a call-up in the production control system. Even autonomous route train systems can be automatically controlled.

FEIG products recommended for automatic material retrieval and refill control:

- MRU102 UHF Universal Reader

- LRU1002 UHF Reader

Milk Run material supply

In the Milk Run system, efficient material provision is the highest priority. It is equally important that the right material appears in the right compartment or at the correct assembly site.

By scanning the part and compartment number, the route train driver is immediately informed whether the part has been delivered to the proper destination. It does not matter whether parts, KLTs and compartments are marked with 1D or 2D barcodes or RFID tags.

The HyWEAR compact product family is ideal for this purpose. Employees with both hands free accelerate the process by up to four seconds per scan. Signal transmitters such as different-colored LEDs, buzzers and vibrating alarms intuitively integrate employees into the process. The sounds immediately confirm the choice or alert the employee in case of an error.

FEIG products recommended for Milk Run

- HyWEAR compact RFID barcode wearables

- ECCO+ RFID Barcode scanner

- SCANNDYbasic Barcode scanner

Smart Order Solution

FEIG also offers Smart Order Solution, a complete decentralized refill control solution at customer consignment warehouses or directly on a construction site. With Smart Order Solution, customers can request material in seconds.

With FEIG's capture devices, products can be marked with either a barcode or an RFID tag. By simply scanning the material or shelf compartment, the material’s information is stored in the device and sent directly to the customer eCommerce platform via the integrated EMMWare Scout software. All this occurs without involving the customer’s IT infrastructure.

FEIG products recommended for Smart Order Solution:

- ECCO+ RFID Barcode scanner

- SCANNDYbasic Barcode scanner