Logistics Services Provider Recalo Tracks Load Carrier With RFID

Turck: Fast HF Read/Write Head with S2 System Redundancy

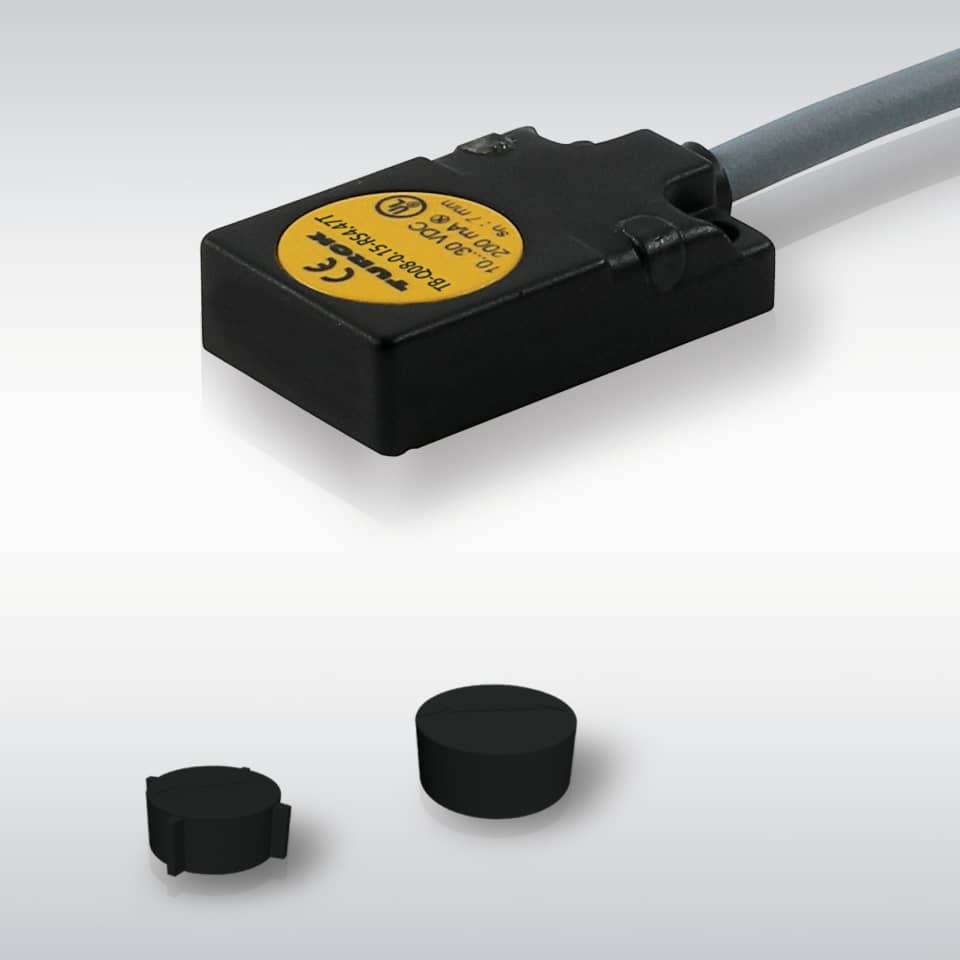

Turck: RFID Read/Write Heads and Tags in Miniature Format

KEB Automation: DRIVERLESS TRANSPORT SYSTEM with RFID Technology

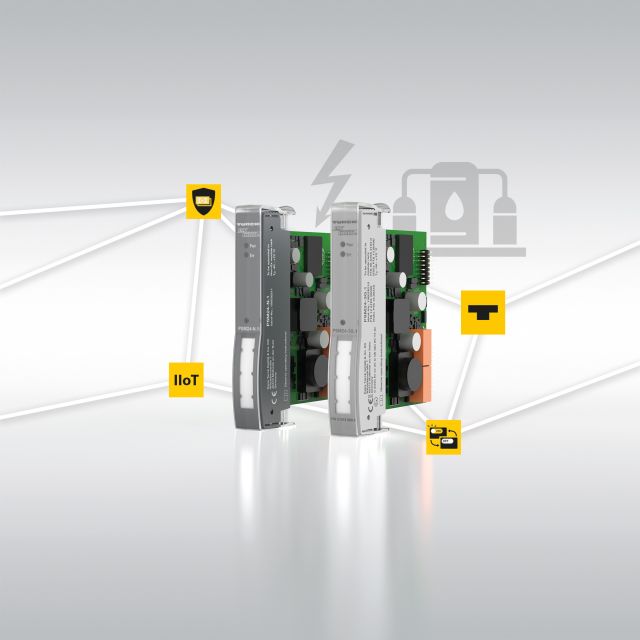

IIoT Power Supply for excom I/O System

💡 Webcast: Battery Production Tracking Solution With RFID Technology at a Leading Chinese Battery Manufacturer

Webinar: Battery Production Tracking with RFID

Turck Establishes Subsidiary in Sweden

KWS ensures seed quality with RFID from Turck

Interview with Turck: Industrial Transformation in 2023

Turck: Condition Monitoring Platform Extended

Turck Presents the TAS IIOT and Service Platform

As an international developer of industrial automation solutions, Turck offers sensor, fieldbus, connection, and interface technology in addition to HMI and RFID products. The company is represented in engineering and construction, the automotive industry, transportation and logistics, the food and packaging industry, and the pharmaceutical industry. After expansion of our palette of UHF products in recent years, Turck has plans to advance and add to this operating area in the next five years.

Christian Wolf, Managing Director, Turck

Turck

Turck is one of the leading manufacturers in industrial automation

With more than 4,500 employees in over 30 subsidiaries as well as sales partners in further 60 countries, the family-owned company is a one-stop shop for RFID Systems.

- Holistic, modular RFID systems for production and logistics processes

- Variety of HF and UHF read/write heads and data carriers for standard and special uses, such as carriers for high temperature conditions up to 210 degrees Celsius, for engine production or use in autoclaves

- Parallel operation of proven HF and far-ranging UHF technology

The Company

Turck is one of the leading manufacturers in industrial automation. With more than 4,500 employees in over 30 subsidiaries as well as sales partners in further 60 countries, the family-owned company is always close to its customers. As a specialist in sensor, fieldbus, connection and interface technology, and also human-machine interfaces (HMI) and RFID systems, Turck offers efficient solutions for factory and process automation.

With their data and communication solutions, they are among the pioneers of the Industrial Internet of Things (IIoT/Industry 4.0).

The Industries

No matter if applied in machine and plant construction, in the sectors of automotive, mobile equipment, transport and handling, food and packaging or in the chemical or pharmaceutical industry, automation solutions and products by Turck increase the availability and efficiency of machines and plants. Industry-specific knowledge, gained through intensive dialog with customers ensure optimal solutions for customer’s automation tasks.

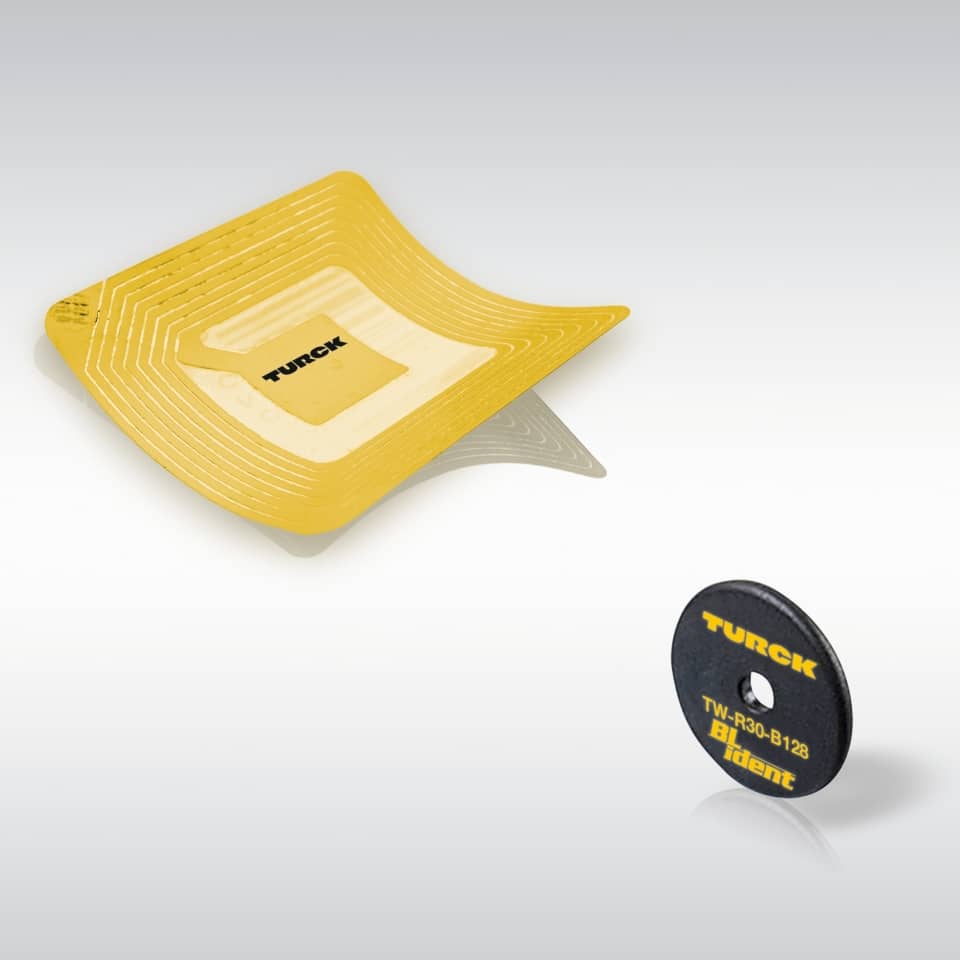

Turck's RFID System BL ident

The BL ident complete RFID system from Turck provides a robust identification solution for use in the production and process automation industries, including everything from production control to distribution and logistics to the whole supply chain management. The RFID system can be implemented effortlessly into nearly every existing automation infrastructure without any programming.

Thanks to protection class IP67 it can also be implemented directly in the machine or system on site. Without the need for control boxes or long signal paths Turck customers save a lot of wiring and installation time.

Since 2017, Turck offers its customers inhouse RFID turnkey solutions. With Turck Vilant Systems the company is able to offer complete system solutions including software, integration and maintenance services. More than 1,000 RFID system installations in 35 countries prove the experience and expertise of Turck Vilant Systems.

Supplier Excellence

Technologies

Application Fields

Get in touch with our experts