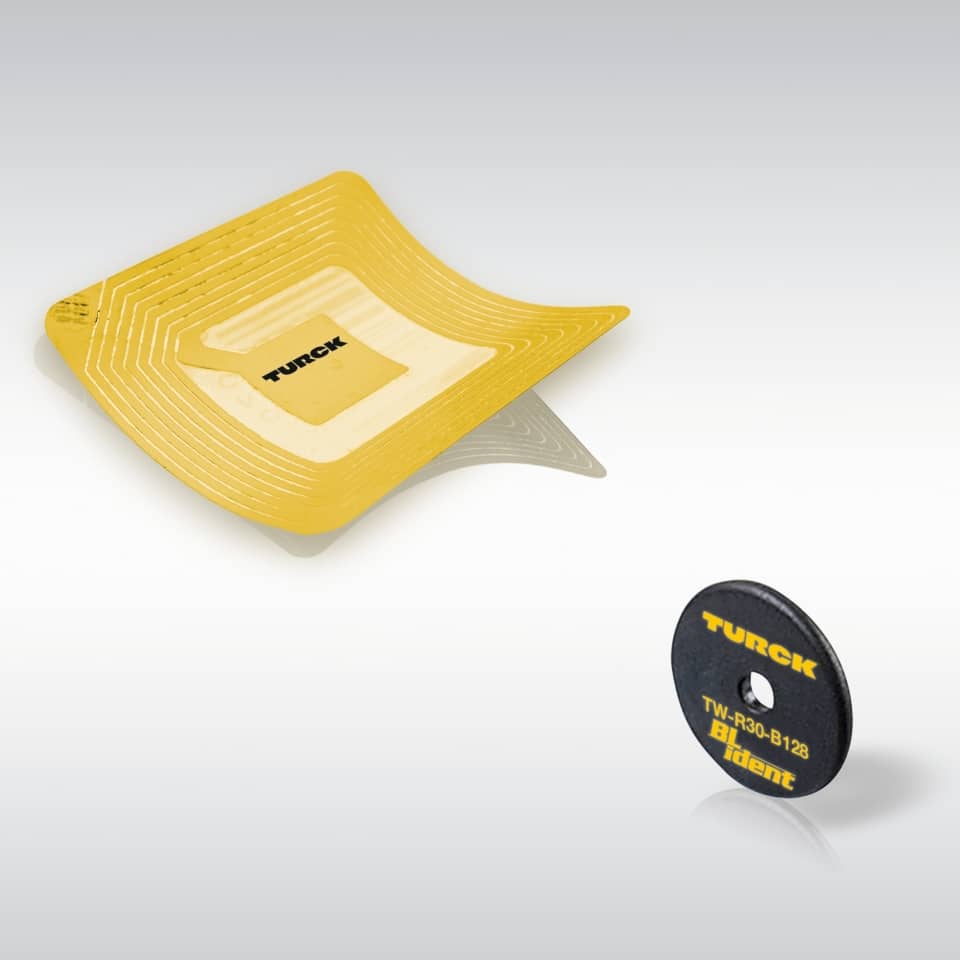

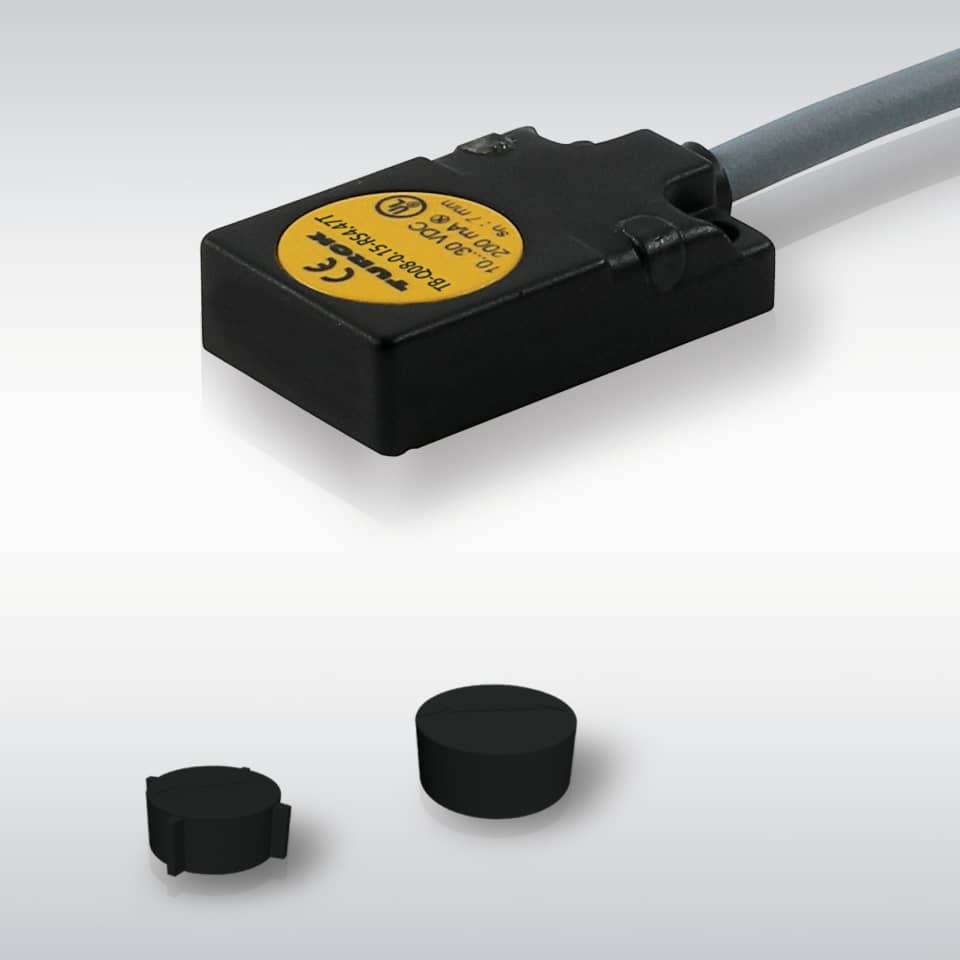

Recalo Tracks Load Carrier With RFID

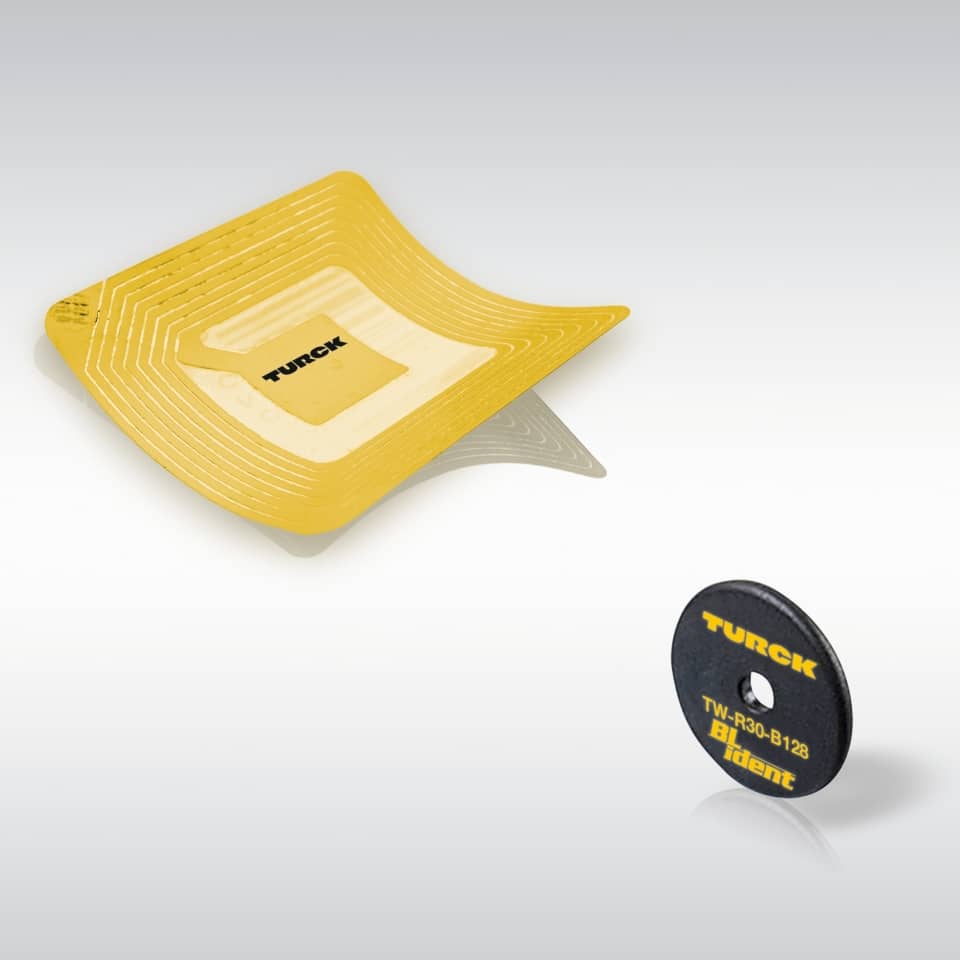

Load Carrier Management Recalo offers its customers the possibility of pooling returnable load carriers, the so-called returnable transport items or RTIs. To always know where a particular load carrier is currently located in the cycle, the company relies on an RFID tracking system from Turck Vilant Systems, which ensures the transparency required for the exact provision of the service to each customer via interfaces to the ERP. To ensure maximum truck utilization, the system even shows employees how high the stacks of boxes need to be in order to make optimum use of the loading capacity. Thanks to this efficiency and the long service life of the RTIs, the Recalo solution effectively reduces its customers' carbon footprint. Author: Jessica Säilä is Head of Marketing at Turck Vilant Systems. Success Story powered by: Think WIOT, Turck Vilant Systems and Turck.